- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

2025 Top 10 Check Valves Trends Innovations and Market Statistics

In recent years, the check valves industry has witnessed significant advancements driven by technological innovations and growing demand across various sectors, including oil and gas, water treatment, and manufacturing. As forecasted by the latest market research report by Global Market Insights, the check valves market is expected to reach a valuation of USD 10 billion by 2025, growing at a CAGR of over 5% from 2021 to 2025. This growth is fueled by the increasing need for efficient fluid management systems and the implementation of stricter regulations on environmental sustainability.

According to industry expert Dr. Alan T. Jarvis, a renowned authority on fluid control systems, "The future of check valves lies in their enhanced durability and performance, allowing for more reliable operations in demanding environments." As we look toward 2025, several emerging trends and innovations are set to reshape the check valves landscape, including the rise of smart technology integration, advancements in material sciences for corrosion resistance, and the adoption of automated systems for better control and efficiency.

This article will explore the top 10 trends and innovations in check valves, emphasizing key market statistics that illustrate the evolving dynamics and opportunities within this critical sector. By understanding these trends, stakeholders can strategically position themselves to leverage the advancements and address the challenges posed by the constantly changing market.

Table of Contents

[Hide]

Emerging Technologies Shaping the Future of Check Valves in 2025

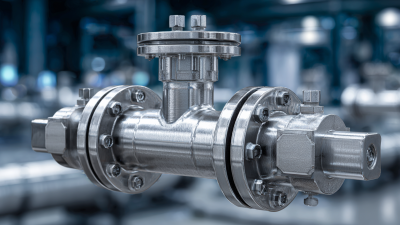

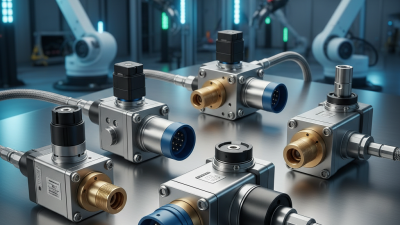

The check valve industry is poised for transformative changes by 2025, driven by remarkable innovations and emerging technologies. Advanced materials such as composite polymers and lightweight metals are significantly enhancing the durability and efficiency of check valves. According to recent market research, the global check valve market is projected to reach USD 12.6 billion by 2025, growing at a CAGR of 4.5% from 2020. This growth is largely attributed to the increasing demand for reliable system automation and fluid control in various sectors including oil and gas, water management, and pharmaceuticals.

Additionally, the integration of smart technologies is a key trend reshaping the future of check valves. The implementation of IoT capabilities allows for real-time monitoring and predictive maintenance, drastically reducing downtime and operational costs. A report from Allied Market Research indicates that the smart valve market, which includes smart check valves, is expected to expand significantly, reflecting the industry's shift towards smarter, data-driven solutions. These innovations are not only enhancing performance but also promoting sustainability through improved energy efficiency and reduced waste, proving that the future of check valves is both innovative and essential for modern industrial applications.

Key Market Trends Driving Check Valve Innovations and Developments

The check valve market is poised for significant advancements, driven by key trends influencing innovation and development. As global industries recognize the necessity of reliable fluid control systems, the demand for high-purity valves—projected to reach $3.45 billion by 2033—underscores the growing emphasis on cleanliness and safety in applications related to food, beverages, and pharmaceuticals. This development reflects a broader shift towards more stringent quality standards across various sectors, thereby boosting the market's growth and attracting investments in advanced manufacturing processes.

Moreover, the expansion of specialized valves, such as those for underwater applications, highlights the industry's versatility and adaptability. The underwater valve market is expected to grow from $365.55 million in 2024 to $476.32 million by 2033, indicating a growing trend towards automation and enhanced reliability in extreme environments. Likewise, the evolving techniques in check valve technology, including the integration of materials like sapphire and ceramic, are set to create new opportunities for innovation. Such advancements are essential as industries strive for improved efficiency and performance, further driving market expansion through advanced research and development efforts.

2025 Top 10 Check Valves Trends Innovations and Market Statistics

| Trend/Innovation | Description | Market Impact (%) | Estimated Growth Rate (CAGR) | Key Drivers |

|---|---|---|---|---|

| Smart Check Valves | Integration of IoT for improved monitoring and control. | 15 | 8% | Increased automation in industries. |

| Sustainable Materials | Use of eco-friendly materials in valve manufacturing. | 12 | 6% | Rising environmental regulations and standards. |

| Enhanced Leakage Prevention | Technologies to minimize leakage in piping systems. | 20 | 7% | Demand for safety and efficiency in operations. |

| Lightweight Designs | Development of lighter materials for easier handling. | 10 | 5% | Logistics and transportation efficiency needs. |

| Automated Systems | Automation technologies reducing manual operations. | 15 | 9% | Increased need for efficiency in industrial processes. |

| Customizable Solutions | Tailored check valves for specific industry needs. | 18 | 10% | Diverse industrial applications and specifications. |

| Real-time Monitoring | Sensors providing live data for valve performance. | 16 | 11% | Growing industries focusing on predictive maintenance. |

| Regulatory Compliance | Meeting stringent regulations in fluid management. | 14 | 6% | Increasing focus on safety and environmental standards. |

| Interchangeable Components | Valves designed for easy replacement of parts. | 9 | 4% | Need for reduced downtime and maintenance costs. |

| Virtual Simulation | Simulation technologies for testing valve performance. | 15 | 8% | Adoption of digital twin technologies in manufacturing. |

Sustainability and Eco-Friendly Materials in Check Valve Manufacturing

Sustainability is increasingly becoming a focal point in check valve manufacturing, as manufacturers strive to reduce their environmental impact and meet regulatory demands. According to a recent market analysis, the global green materials market is projected to reach $600 billion by 2025, marking a significant growth in demand for eco-friendly components in industrial applications, including check valves. Notable trends include the adoption of bioplastics and recycled metals, which not only minimize waste but also enhance the lifecycle of valve products.

Moreover, innovative technologies are being implemented to optimize energy efficiency in manufacturing processes. A report from the American Society of Mechanical Engineers indicates that using renewable energy sources during production can decrease the carbon footprint by up to 50%. Additionally, companies that switch to eco-friendly materials in their valve designs not only contribute to sustainability efforts but also gain a competitive advantage, as clients are increasingly favoring suppliers who prioritize environmental responsibility. This shift towards sustainable practices is reshaping the check valve market, aligning it with global trends of environmental stewardship and corporate responsibility.

2025 Top 10 Check Valve Trends Innovations and Market Statistics

The following chart illustrates the trends in sustainability and the use of eco-friendly materials in the manufacturing of check valves for the year 2025. The data reflects the prominence of various innovative materials and technologies being adopted in the industry.

Impact of Automation and IoT on Check Valve Functionality and Design

The integration of automation and the Internet of Things (IoT) is significantly transforming the functionality and design of check valves. These advancements enable more precise control and monitoring of fluid systems, leading to enhanced efficiency and reliability. With real-time data transmission, check valves can operate more intelligently, allowing for timely responses to changes in pressure and flow rates. This responsiveness not only minimizes the risk of backflow but also optimizes energy consumption and extends the lifespan of the entire system.

Moreover, the design of check valves is evolving to accommodate these technological enhancements. Traditional mechanical designs are being complemented, or in some cases replaced, by smart valves equipped with sensors and communication capabilities. This smart technology facilitates predictive maintenance, as operators can receive alerts about potential failures before they happen. Consequently, manufacturers are focusing on creating more adaptable and modular check valves that can seamlessly integrate into IoT ecosystems, ensuring that they meet the growing demands for automation across various industries.

Regional Market Insights: Growth Opportunities for Check Valve Industries in 2025

In 2025, the check valve industry is poised for significant growth driven by increasing demand across various sectors including oil and gas, water treatment, and manufacturing. According to a recent market report by MarketsandMarkets, the global check valves market is expected to reach USD 6.2 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.3% from 2020. This growth can be largely attributed to the rising investments in infrastructure and industrial expansion, particularly in emerging markets such as Asia-Pacific and the Middle East.

Regional market insights reveal that North America will continue to be a leading market, driven by stringent regulations and the need for advanced safety systems in existing infrastructure. Meanwhile, Asia-Pacific is anticipated to exhibit the highest growth rate due to rapid urbanization and expanding manufacturing sectors. Countries like India and China are investing heavily in modernization, thus presenting lucrative opportunities for check valve manufacturers.

**Tips:** To maximize growth potential in regional markets, companies should focus on forming strategic partnerships and alliances. Additionally, investing in R&D for innovative valve designs can offer a competitive edge. Understanding local regulations and compliance requirements will also aid in navigating market entry effectively.

Related Posts

-

Understanding the Role of Check Valves in Modern Industrial Systems

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications

-

7 Essential Tips for Mastering Hydraulic Controls in Your Projects

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance

-

2025 Top 5 Proportional Valves to Enhance Your Industrial Efficiency