- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

How to Choose the Right Hydraulic Unit for Your Industrial Needs

When choosing the right hydraulic unit for your industrial needs, it is imperative to consider several factors that ensure optimal performance and efficiency. According to the International Fluid Power Society (IFPS), the global hydraulic equipment market is projected to reach $50 billion by 2026, with hydraulic units being a critical component in various sectors such as manufacturing, construction, and automotive industries. The right hydraulic unit not only enhances productivity but also contributes to energy savings, with reports indicating that properly selected hydraulic systems can reduce energy consumption by up to 30%.

Furthermore, the integration of advanced technology in hydraulic units has led to significant improvements in control, efficiency, and reliability. Research from the Software & Information Industry Association (SIIA) highlights that industries utilizing smart hydraulic systems experience a reduction in operational downtime by approximately 20%, translating to cost savings and improved workflow efficiency. Therefore, understanding your specific requirements, including the operating environment and application demands, becomes essential in selecting the most suitable hydraulic unit that aligns with your operational goals and drives overall performance.

Table of Contents

[Hide]

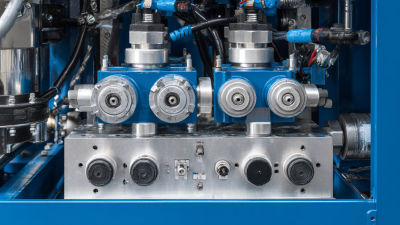

Key Features to Evaluate in Hydraulic Units for Industrial Applications

When selecting a hydraulic unit for industrial applications, evaluating key features is essential to ensure optimal performance and compatibility with your specific needs. First, consider the unit's pressure capabilities. The maximum pressure rating should align with the demands of your machinery or process to prevent failures or inefficiencies. Additionally, the flow rate is critical; a unit should provide sufficient hydraulic fluid flow to maintain productivity without overstressing the system.

Another vital feature is the type of pump used in the hydraulic unit. Different applications may require gear, piston, or vane pumps, each offering unique advantages in terms of efficiency and durability. Furthermore, the unit's size and weight can influence installation and operational flexibility, especially in tight or mobile environments. Also, assess the compatibility of the hydraulic unit with existing hydraulic fluids, as using the wrong type can lead to system damage. Overall, thorough evaluation of these features will guide you in selecting the right hydraulic unit tailored for your industrial requirements.

Hydraulic Units for Industrial Applications: Key Features Evaluation

Top 5 Hydraulic Unit Types and Their Best Use Cases

When selecting a hydraulic unit for industrial applications, understanding the different types available can significantly influence efficiency and performance.

The first type is the gear pump, renowned for its durability and ability to handle high viscosity fluids. It’s often used in applications requiring consistent pressure and flow, such as in hydraulic lifts and construction machinery.

Another common type is the piston pump, which is ideal for high-pressure applications. Its design allows for precise control of flow rates, making it suitable for tasks that demand high accuracy, such as injection molding and metal forming operations.

On the other hand, vane pumps are favored for their versatility and quiet operation, often found in automotive hydraulic systems and machine tools.

Lastly, hydraulic power packs offer a complete and self-contained hydraulic system, making them perfect for portable applications. Their versatility caters to various industrial needs, from powering hydraulic tools to supporting complex automation systems.

As each type serves distinct purposes, understanding their characteristics can lead to more informed decisions tailored to specific operational requirements.

10 Essential Questions to Ask Before Purchasing a Hydraulic Unit

When selecting a hydraulic unit for industrial applications, it's crucial to ask the right questions to ensure compatibility, efficiency, and reliability. First, consider the hydraulic fluid type. According to the Hydraulic Institute's 2021 report, choosing the appropriate fluid can significantly enhance system performance and reduce maintenance costs. It's essential to verify whether your machinery requires biodegradable fluids or if mineral oils are acceptable, influencing both operational efficiency and environmental impact.

Next, assess the required pressure and flow rates. A 2022 study by the International Fluid Power Society indicates that improper sizing of hydraulic units can lead to a reduction in performance by up to 30%. Understanding the specific demands of your operation, including peak pressure and expected flow, allows for the selection of a unit that meets these needs without excess expenditure on energy or wear. Furthermore, inquiry about the manufacturer's service and support capabilities can determine long-term reliability. A well-supported unit can reduce downtime and enhance productivity, making it a critical aspect of the purchase decision.

Best Practices for Sizing Hydraulic Units to Meet Industrial Demands

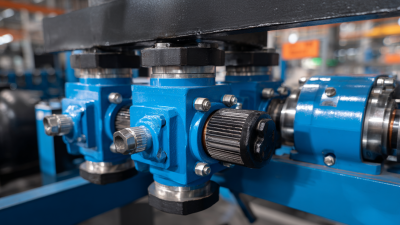

When it comes to sizing hydraulic units for industrial applications, several best practices should be considered to ensure optimal performance and reliability. First, it is crucial to assess the specific requirements of the machinery and operations that the hydraulic unit will support. This includes understanding the maximum pressure needed, the flow rate required, and the type of hydraulic system being employed. By establishing these parameters, you can select a hydraulic unit that not only meets the current demands but can also adapt to future needs.

Another important factor is the compatibility of the hydraulic components. Ensuring that the hydraulic unit is compatible with existing systems—such as pumps, valves, and actuators—can prevent performance issues and enhance efficiency. Additionally, consider the unit’s energy efficiency and maintenance needs, as modern designs often focus on reducing operational costs and increasing lifespan. By following these guidelines, you can make an informed decision when choosing the right hydraulic unit to meet industrial demands effectively.

7 Common Mistakes to Avoid When Choosing a Hydraulic Unit

When selecting a hydraulic unit for industrial applications, avoiding common mistakes can save both time and money. One significant pitfall is underestimating the required pressure and flow rate. Many buyers focus too much on initial price rather than the performance capabilities. This can lead to choosing a unit that doesn’t meet operational demands, resulting in decreased efficiency and increased wear over time.

Another frequent error is neglecting compatibility with existing systems. It’s crucial to consider the specifications of other equipment in your facility, as mismatched units can lead to failure or inefficient operation. Additionally, overlooking maintenance requirements can be detrimental. Selecting a unit that is difficult to maintain can result in higher downtime and costs in the long run. By being aware of these common mistakes, you can make a more informed decision when choosing the right hydraulic unit for your needs.

Related Posts

-

The Essential Guide to Understanding Hydraulic Power Packs in Industrial Applications

-

2025 Top 5 Proportional Valves to Enhance Your Industrial Efficiency

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications

-

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications