- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

What is Control Products and How They Enhance Efficiency in Industrial Applications

Control products have become a cornerstone of modern industrial applications, playing an essential role in enhancing operational efficiency across various sectors. According to a recent report by MarketsandMarkets, the global control products market is projected to reach $135 billion by 2025, growing at a CAGR of 6.3% from 2020. This growth underscores the increasing reliance of industries on advanced control systems to optimize processes and reduce costs.

Industry experts assert that the integration of these control products not only streamlines operations but also significantly boosts productivity. Dr. Jane Holloway, a leading figure in industrial automation, remarked, "The effective implementation of control products provides companies with the agility to adapt to market changes, thus ensuring sustained growth and competitiveness.” As sectors such as manufacturing, energy, and logistics continue to evolve, the demand for sophisticated control solutions has never been more pronounced.

In this context, companies that leverage innovative control products are positioned to gain a substantial edge. As we explore the top 10 control products of 2025 and their impact on industrial efficiency, it becomes clear that these technologies are not merely enhancements but integral components necessary for success in today's dynamic market landscape.

Table of Contents

[Hide]

Understanding Control Products and Their Role in Industry

Control products are essential components in industrial applications, significantly contributing to operational efficiency and effectiveness. These products, which include sensors, controllers, and automation systems, play a crucial role in monitoring and regulating various processes. According to a report by MarketsandMarkets, the global industrial automation market is projected to reach USD 296.70 billion by 2026, growing at a CAGR of 9.2% from 2021. This growth underscores the increasing reliance on control products for optimizing workflows and enhancing productivity in various sectors, including manufacturing, oil and gas, and food and beverage.

Moreover, control products enhance efficiency by enabling real-time data collection and analysis, which allows industries to make informed decisions rapidly. For instance, a McKinsey report indicates that organizations that effectively leverage automation and control systems can improve their operational efficiencies by up to 30%. This capacity not only lowers operational costs but also minimizes downtime, facilitating a more agile response to market demands. As industries continue to face challenges in resource management and supply chains, the role of control products becomes increasingly vital in driving innovation and sustaining competitive advantage.

Types of Control Products Used in Industrial Processes

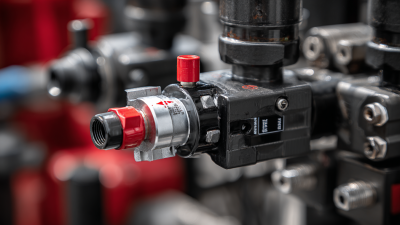

Control products play a crucial role in optimizing industrial processes by ensuring precision and reliability in operations. Among the various types of control products, sensors, actuators, and controllers are essential components. According to a report by MarketsandMarkets, the sensors market is expected to grow from USD 190.8 billion in 2021 to USD 289.5 billion by 2026, indicating their rising importance in industrial applications. These sensors help monitor key parameters such as temperature, pressure, and humidity, enabling real-time data analysis and improving decision-making.

Actuators, on the other hand, are vital for converting control signals into physical action. They are widely used in manufacturing processes to automate machinery, enhancing production speed and efficiency. A study published by ResearchAndMarkets highlights that the global actuator market is projected to reach USD 85.6 billion by 2027, driven by the increasing demand for smart automation solutions. Finally, controllers orchestrate these components by managing input data from sensors and sending commands to actuators, facilitating seamless operation across multiple systems. This integration of control products not only boosts productivity but also aids in minimizing downtime, ultimately leading to cost savings for industries.

Efficiency of Control Products in Industrial Applications

How Control Products Improve Operational Efficiency

Control products are critical components in various industrial applications, playing a pivotal role in enhancing operational efficiency. According to a report by MarketsandMarkets, the global market for industrial automation, which includes control products, is expected to reach $296 billion by 2026, growing at a CAGR of 9.2% from 2021. This growth underscores the increasing reliance on advanced control systems to streamline operations and boost productivity.

One significant way control products improve operational efficiency is through automation. By automating routine tasks, industries can significantly reduce human error and operational downtime. For instance, a study by McKinsey & Company found that automating control processes can lead to a 20-30% increase in productivity in manufacturing. Furthermore, control products enable real-time monitoring and adjustments within systems, facilitating quicker decision-making and resource allocation. This capability ensures that production lines operate smoothly, maximizing output while minimizing waste—essential factors that contribute to the overall efficiency of industrial operations.

Implementing Control Products for Maximum Effectiveness

Implementing control products in industrial applications can significantly enhance operational efficiency. By automating processes and providing real-time data, these products allow organizations to streamline production workflows. For instance, advanced sensors and control systems can monitor equipment performance and detect anomalies, enabling timely interventions that prevent costly downtime. This proactive approach not only reduces maintenance costs but also improves overall productivity.

In addition to improving efficiency, integrating control products fosters better decision-making. With accurate data analytics, managers gain insights into process performance and resource utilization. This information can be leveraged for strategic planning, leading to optimized operations. Moreover, implementing control products supports sustainability initiatives by minimizing waste and energy consumption. Companies that harness the power of these technologies are better positioned to adapt to market changes, maintain competitiveness, and achieve long-term success.

Future Trends in Control Products and Industrial Efficiency

The landscape of industrial efficiency is rapidly evolving, particularly with advancements in control products. These devices, which regulate and automate processes, are integral to enhancing productivity and minimizing waste. As industries seek to optimize their operations, the future of control products is becoming more intertwined with technologies like the Internet of Things (IoT) and artificial intelligence (AI). These trends are driving the development of smarter, more adaptive control systems that can learn from data patterns and adjust processes in real-time, leading to unprecedented efficiency levels.

Tips: To stay ahead, consider integrating IoT-enabled control products into your operations. This can facilitate predictive maintenance, reducing downtime, and improving overall workflow. Additionally, investing in training for your staff on these new technologies can help maximize their benefits and ensure seamless integration into your existing processes.

Moreover, sustainability is becoming a crucial factor in choosing control products. Future trends indicate a significant shift towards energy-efficient solutions that reduce carbon footprints while maintaining productivity. Automation will play a key role in achieving these sustainability goals, allowing for optimized resource use and waste reduction through better monitoring and control of industrial processes.

Tips: Evaluate your current systems to identify areas where energy-efficient control products can be implemented. Regular audits and updates can help you maintain a lean, eco-friendly operation that supports long-term sustainability goals.

Related Posts

-

Exploring Innovative Control Products: Transforming Industries with Smart Technology

-

Maximizing Efficiency: How Directional Control Valves Transform Hydraulic Systems

-

The Essential Guide to Understanding Hydraulic Power Packs in Industrial Applications

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications

-

What is a Pilot Operated Check Valve and How Does It Work in Hydraulic Systems