- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

The Essential Guide to Understanding Pressure Relief Valves: Safety and Function Explained

Pressure relief valves (PRVs) play a critical role in maintaining safety and functionality across various industries, particularly in the chemical and energy sectors. According to a report by Research and Markets, the global pressure relief valve market is projected to grow from $4.8 billion in 2021 to over $7 billion by 2026, highlighting their increasing importance in managing system pressure and preventing hazardous situations. These valves are essential for protecting equipment and personnel from the dangers of overpressure, which can lead to catastrophic failures. Understanding the operation, types, and applications of pressure relief valves is vital for engineers and safety professionals alike. This essential guide aims to provide a comprehensive overview of PRVs, their safety features, and their proper functioning, ensuring that industry stakeholders can make informed decisions for effective risk management.

Table of Contents

[Hide]

Overview of Pressure Relief Valves: Types and Applications

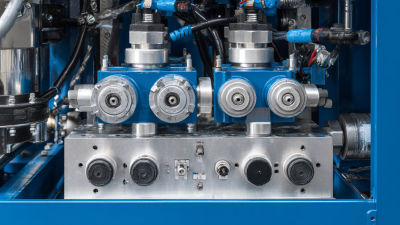

Pressure relief valves (PRVs) are critical safety devices used in various industries to prevent system failures due to overpressure. They work by automatically releasing excess pressure when it exceeds a predetermined limit, ensuring that equipment and personnel remain safe from potential hazards. Understanding the types and applications of pressure relief valves is essential for proper selection and maintenance.

There are several types of pressure relief valves, including spring-loaded, pilot-operated, and rupture disc valves. Spring-loaded valves are the most common and are often found in water supply systems, heating, and gas applications. Pilot-operated valves, on the other hand, provide more precise control and are typically used in larger systems where pressure swings are common. Rupture discs are non-reclosing devices that offer a quick release of pressure, making them valuable in critical safety applications.

**Tips: To ensure the proper functioning of pressure relief valves, regular maintenance and inspection are crucial. Check for signs of wear or damage, and make sure the valve’s setting is calibrated correctly. Additionally, familiarize yourself with the specific application and user manual to maximize efficiency and safety.** Selecting the right type of PRV based on the application can significantly impact safety and operational effectiveness.

The Essential Guide to Understanding Pressure Relief Valves: Types and Applications

This chart illustrates the distribution of different types of pressure relief valves used in various applications, highlighting their safety and functional significance.

Understanding the Safety Function of Pressure Relief Valves

Pressure relief valves (PRVs) play a crucial role in maintaining safety across various industrial applications. These devices are engineered to prevent excess pressure buildup by automatically releasing pressure when it exceeds a predefined limit. According to the American Society of Mechanical Engineers (ASME), nearly 50% of industrial accidents can be attributed to pressure system failures, highlighting the importance of effective safety measures like PRVs. By ensuring safe operations within vessels and piping, PRVs help to avert catastrophic equipment failures and maintain operational integrity.

In terms of function, PRVs not only safeguard equipment but also protect personnel and the environment. The National Board of Boiler and Pressure Vessel Inspectors reports that improper management of pressure systems can lead to financial losses exceeding $1 billion annually for industries. Implementing well-designed pressure relief systems can significantly mitigate such risks and enhance overall workplace safety. Key factors that contribute to the effective performance of PRVs include correct sizing, appropriate materials, and regular maintenance checks, all of which are vital in ensuring that these critical components function effectively when needed.

The Essential Guide to Understanding Pressure Relief Valves

| Parameter | Description | Importance |

|---|---|---|

| Set Pressure | The pressure at which the valve opens to release excess pressure. | Crucial for preventing equipment damage and ensuring system safety. |

| Relief Capacity | The maximum flow rate the valve can handle when it opens. | Essential for determining if the valve can adequately protect the system. |

| Lift Type | Indicates whether the valve is a spring-operated or pilot-operated type. | Affects sensitivity and response time of the valve. |

| Material | The composition of the valve body (e.g., stainless steel or brass). | Influences durability, corrosion resistance, and suitability for various media. |

| Testing & Certification | Indicates if the valve meets industry safety standards. | Important for ensuring compliance and reliability of the valve. |

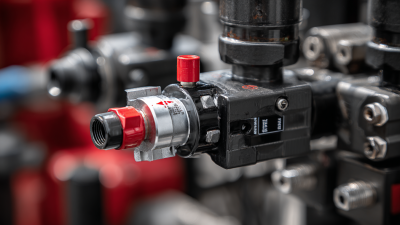

Key Components and Mechanisms of Pressure Relief Valves

Pressure relief valves (PRVs) are critical safety devices designed to prevent excessive pressure buildup in various systems. Understanding their key components and mechanisms is essential for ensuring their effective operation. A typical PRV consists of several important parts: the body, the disc, the spring, and the actuator. The body houses the internal components and connects to the system it safeguards, while the disc serves as the primary sealing mechanism. The spring, which is calibrated to a specific pressure setting, keeps the disc in place until a predetermined pressure level is reached.

When the system pressure exceeds this preset limit, the actuator mechanism is triggered. This causes the disc to lift off its seat, allowing excess pressure to vent safely from the system. Different types of PRVs, such as spring-loaded, pilot-operated, and balanced bellows, leverage various mechanisms to achieve this function efficiently. By comprehensively understanding these components and their interactions, operators can ensure that PRVs perform their essential role in maintaining system safety and preventing catastrophic failures.

Installation and Maintenance Best Practices for Pressure Relief Valves

Pressure relief valves (PRVs) are critical components in ensuring the safety and functionality of various systems by preventing excessive pressure buildup. Proper installation of these valves is essential not only for compliance with safety regulations but also for optimizing their performance. According to the American Society of Mechanical Engineers (ASME), nearly 70% of failures in pressure relief systems can be traced back to improper installation. It's crucial for engineers to follow manufacturer guidelines and industry standards, ensuring that PRVs are positioned correctly and connected to the right piping systems.

Regular maintenance and inspection of pressure relief valves can significantly extend their service life and enhance system reliability. A report from the National Board of Boiler and Pressure Vessel Inspectors highlights that routine testing can detect deviations in performance, allowing for timely interventions that can prevent system failures. Industry best practices recommend a bi-annual inspection schedule, including visual assessments and functional testing to ensure valves open at their designated set pressures. Adhering to such maintenance protocols not only safeguards equipment but also adheres to regulatory compliance, ultimately benefiting operational efficiency.

Common Issues and Troubleshooting Tips for Pressure Relief Valves

Pressure relief valves (PRVs) are critical components in industrial systems, designed to prevent overpressure conditions that can lead to equipment failure and safety hazards. However, like any mechanical system, PRVs are not immune to common issues that can compromise their performance. According to a report by the American Society of Mechanical Engineers (ASME), approximately 30% of safety valve failures could be attributed to improper maintenance and common faults such as corrosion, fouling, and valve seat wear. Regular inspection and maintenance are essential to ensure optimal operation and mitigate risks.

Troubleshooting PRVs involves examining several key indicators. For instance, if a valve fails to open at its set pressure, this may signal issues with the spring mechanism or internal wear. Conversely, if a valve continually leaks, it may point to seat damage or debris preventing a proper seal. The Hydraulic Institute suggests that up to 25% of PRV failures could be minimized through routine testing and immediate corrective action when issues are detected.

Implementing a scheduled maintenance routine not only enhances the reliability of pressure relief systems but also contributes significantly to operational safety and efficiency in industrial processes.

Related Posts

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance

-

Maximizing Efficiency: How Directional Control Valves Transform Hydraulic Systems

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

The Essential Guide to Understanding Hydraulic Power Packs in Industrial Applications

-

Exploring Innovative Control Products: Transforming Industries with Smart Technology

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications