- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

7 Essential Tips for Mastering Hydraulic Controls in Your Projects

In the realm of engineering and construction, hydraulic controls play a pivotal role in the efficient operation of various machinery and systems. According to a recent industry report by Technavio, the global hydraulic equipment market is expected to grow by over 5% annually, underscoring the increasing reliance on hydraulic systems across multiple sectors, including agriculture, manufacturing, and construction. Mastering hydraulic controls is not merely beneficial; it is an essential skill for professionals looking to optimize performance and enhance productivity in their projects.

As machines become more advanced, the importance of understanding hydraulic controls cannot be overstated. The ability to troubleshoot and fine-tune these systems can lead to significant improvements in efficiency and safety. A comprehensive study from the International Journal of Fluid Power highlights that improper handling of hydraulic systems can result in maintenance costs up to 30% higher than necessary, illuminating the financial impact of mastering these controls. By focusing on essential strategies for managing hydraulic systems, professionals can not only enhance their project outcomes but also contribute to the sustainability and reliability of hydraulic applications in their respective fields.

Table of Contents

[Hide]

Understanding the Basics of Hydraulic Systems for Effective Control

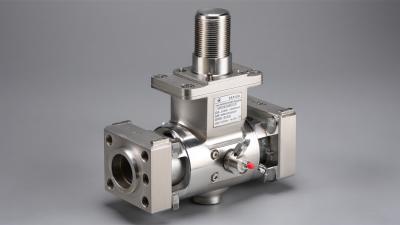

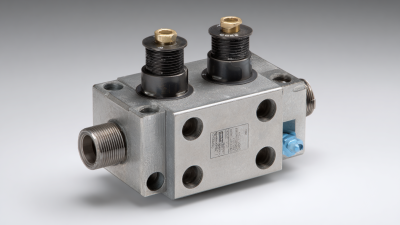

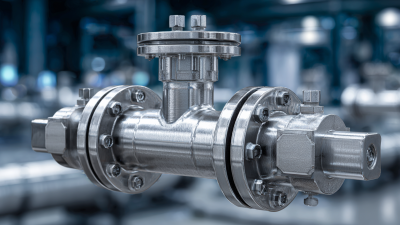

Understanding the basics of hydraulic systems is crucial for effective control in various projects. Hydraulic systems rely on the principles of fluid mechanics to transmit power through liquid. Familiarizing yourself with components such as pumps, valves, actuators, and reservoirs is fundamental. Each component plays a unique role: pumps generate flow, valves control direction and flow rate, and actuators execute the work. Mastery of these components enables project managers and engineers to design more efficient systems and troubleshoot issues effectively.

In addition to knowing the components, comprehending how hydraulic pressure works is essential. Pressure is the driving force that allows hydraulic systems to operate seamlessly. By understanding Pascal's law, which states that pressure applied to a confined fluid is transmitted undiminished in all directions, professionals can better predict system behavior under varying loads and conditions. This knowledge is not only critical for ensuring safety and reliability but also for optimizing performance, allowing for smoother operations and longer equipment life. Taking the time to grasp these fundamentals will significantly enhance your ability to manage and control hydraulic systems in any project.

7 Essential Tips for Mastering Hydraulic Controls in Your Projects

| Tip | Description | Benefits |

|---|---|---|

| 1. Understand Basic Components | Familiarize yourself with pumps, cylinders, valves, and reservoirs. | Improved troubleshooting and system design. |

| 2. Learn System Diagrams | Study hydraulic schematics to understand flow and control. | Faster interpretation during maintenance. |

| 3. Prioritize Safety | Always follow safety protocols when working with hydraulic systems. | Prevention of accidents and injuries. |

| 4. Proper Fluid Selection | Choose the right hydraulic fluid for your application. | Optimal performance and longevity of components. |

| 5. Regular Maintenance | Schedule routine checks and servicing of hydraulic equipment. | Reduced downtime and increased reliability. |

| 6. Control Systems Knowledge | Understand different hydraulic control methods including proportional, directional, and flow control. | Enhanced precision in controlling hydraulic operations. |

| 7. Stay Updated | Keep abreast of the latest technologies and advancements in hydraulic systems. | Ability to implement cutting-edge solutions in projects. |

Key Components: Identifying Essential Parts of Hydraulic Controls

When mastering hydraulic controls in your projects, understanding the key components is vital. Hydraulic systems rely on a few essential parts, including pumps, valves, actuators, and reservoirs. Pumps are responsible for generating flow and pressure, while valves control the flow direction, pressure, and speed of the hydraulic fluid. Actuators, such as cylinders and motors, provide the necessary motion, and reservoirs store fluid for the system. Knowing how these components interact is crucial for efficient design and operation.

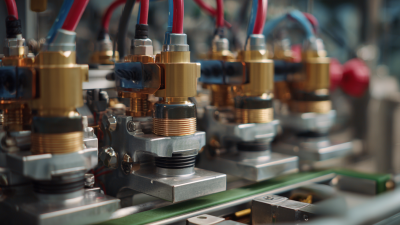

Recent advancements in hydraulic technology, particularly in industries like construction and mining, highlight the importance of proper system modeling. For example, research on excavator manipulator systems illustrates the necessity of integrating mechanical and hydraulic subsystems for optimal performance. By utilizing simulation and design development tools, engineers can enhance the reliability and efficiency of hydraulic controls. Prioritizing maintenance and routine inspections will ensure these systems operate smoothly, ultimately contributing to the success of any project that employs hydraulic technology.

Tips for Troubleshooting Common Hydraulic Control Issues

Hydraulic control systems are critical in various applications, but they can sometimes present challenges. One common issue is the presence of air in the hydraulic fluid, which can lead to reduced efficiency and erratic system behavior. To troubleshoot this, ensure that you properly bleed the hydraulic lines to remove any air pockets. Regular maintenance, including checking fluid levels and inspecting for leaks, can also prevent air from entering the system in the first place.

Another frequent problem is inconsistent actuator movement, which may be due to blockages or poor fluid quality. To address this, start by examining the hydraulic lines and filters for any obstructions. Use clean hydraulic fluid that meets the manufacturer's specifications to ensure optimal performance. Additionally, monitoring the system for unusual noises or vibrations can alert you to potential issues before they escalate, allowing you to take corrective action promptly.

Regular inspections and proactive maintenance are essential to keep hydraulic controls functioning smoothly and reliably.

Optimizing Performance: Best Practices for Maintenance and Care

When it comes to hydraulic systems, maintenance and care are crucial for optimizing performance. According to the International Fluid Power Society (IFPS), regular maintenance can reduce equipment failure rates by up to 40%. This statistic underscores the importance of adhering to a planned maintenance schedule that includes inspecting hydraulic fluid levels, checking for leaks, and ensuring that filters are clean. Implementing a proactive maintenance strategy not only extends the lifespan of components but also enhances overall system efficiency.

Additionally, proper fluid management is vital for hydraulic performance. The Hydraulic Institute recommends monitoring fluid temperatures and keeping them within the ideal range to prevent thermal degradation, which can significantly affect system functionality. Utilizing high-quality hydraulic fluids that meet industry standards can also improve performance metrics. For example, a study published by the National Fluid Power Association (NFPA) revealed that systems using optimized fluids demonstrated a 15% improvement in energy efficiency. By prioritizing maintenance and fluid quality, project managers can ensure their hydraulic systems operate at peak performance levels and achieve maximum productivity.

Advanced Techniques for Enhancing Hydraulic System Efficiency

Hydraulic systems are vital in many industrial applications, and mastering their controls can significantly enhance overall efficiency. According to the International Journal of Fluid Power, optimizing hydraulic control systems can lead to improvements of up to 20% in energy consumption. This is particularly important as industries face increasing pressure to reduce operational costs and energy usage.

One of the most effective tips for enhancing hydraulic system efficiency is to regularly maintain and calibrate the hydraulic controls. This ensures that the system operates at peak performance, thus minimizing energy losses due to leaks or malfunctions. Additionally, integrating advanced sensors can provide real-time data on system performance, enabling proactive adjustments that maintain efficiency.

Another key technique is the effective use of variable displacement pumps, which adapt the flow to match the load requirements. Studies have shown that systems employing these pumps can achieve energy savings of around 15-30%. By implementing these advanced techniques and leveraging data analytics, project managers can not only extend the lifespan of hydraulic systems but also significantly boost their overall performance.

Related Posts

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Why Hydraulic Flow Control Valves are Essential for Optimizing System Performance: Insights and Data

-

What is a Pilot Operated Check Valve and How Does It Work in Hydraulic Systems

-

Exploring Innovative Control Products: Transforming Industries with Smart Technology

-

The Future of Automation: How Servo Valves are Revolutionizing Industry Efficiency

-

Understanding the Role of Check Valves in Modern Industrial Systems