- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Why Flow Control Valve is Essential for Effective System Performance

In today's increasingly complex industrial landscape, maintaining optimal system performance has become paramount. One of the critical components that facilitate this performance is the flow control valve. According to a report by Research and Markets, the global flow control valve market is projected to reach USD 9.7 billion by 2026, highlighting its significant role across various sectors, including oil and gas, water treatment, and manufacturing. These valves are vital for regulating fluid flow, ensuring efficiency, and enhancing the reliability of systems that rely on precise control of fluid dynamics.

The importance of flow control valves extends beyond mere functionality; they significantly contribute to energy efficiency and operational cost savings. A study from the International Energy Agency indicates that optimizing fluid flow in industrial processes can reduce energy consumption by up to 30%. This not only leads to substantial economic benefits but also aligns with global sustainability goals by minimizing the carbon footprint associated with excessive energy use. As industries strive for greater efficiency while adhering to stricter environmental regulations, the role of flow control valves becomes increasingly indispensable, serving as a cornerstone for effective system performance.

Table of Contents

[Hide]

What is a Flow Control Valve and its Function in Fluid Systems

A flow control valve is a crucial component in fluid systems, serving to regulate the flow rate and pressure of liquids or gases within a system. By adjusting the valve position, operators can control the amount of fluid passing through, ensuring that it meets specific system requirements. This function is vital for maintaining the efficiency and stability of various industrial applications, including hydraulic systems, pneumatic systems, and water supply networks.

The primary purpose of a flow control valve is to provide precise management of fluid dynamics. This is achieved through different mechanisms such as throttling, where the valve partially obstructs the flow to reduce the volume or speed. By optimizing the flow rate, the valve helps in preventing issues such as cavitation, excess pressure, and system overload, which can compromise performance and lead to potential failures. In summary, flow control valves are integral to the efficient operation of fluid systems, ensuring that resources are utilized effectively while maintaining safe operational standards.

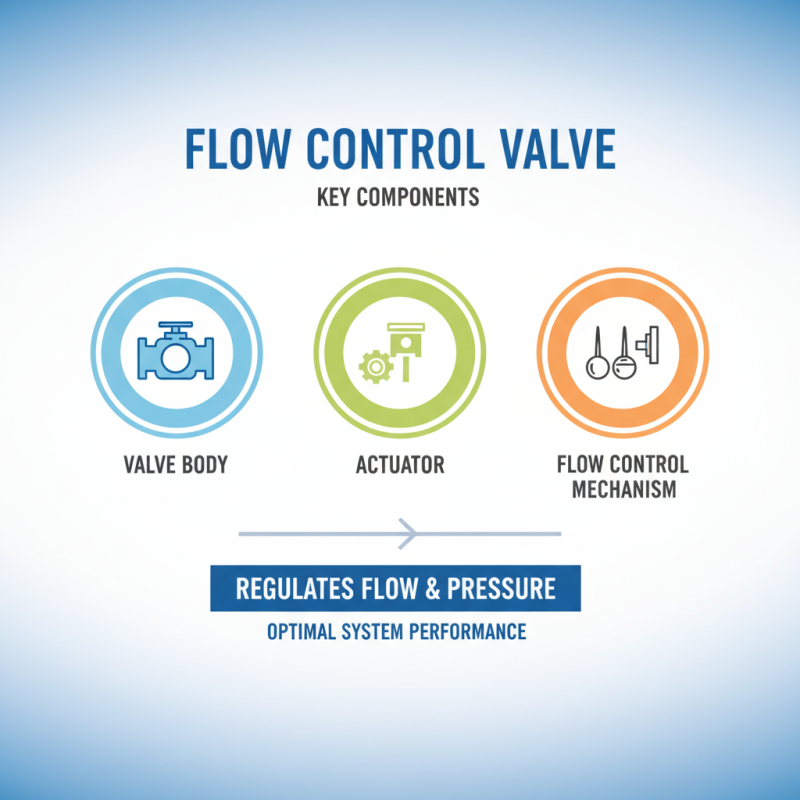

Key Components of Flow Control Valves and Their Role in Performance

Flow control valves are critical components in various systems that require precise management of fluid movement. Understanding the key components of these valves can significantly enhance system performance. The primary parts include the valve body, actuator, and the flow control mechanism itself, which can be a needle, ball, or slide. Each of these components plays a crucial role in regulating the flow rate and pressure within the system, allowing for optimal operation and efficiency.

Proper maintenance of flow control valves is equally important for sustained performance. Regular inspections can help identify wear and tear that may impact functionality. Additionally, ensuring that the actuator responds accurately to the control signal is essential for maintaining the desired flow rate. If malfunctions are detected, immediate action should be taken to either recalibrate or replace the faulty components.

Tips: To improve the longevity and performance of your flow control valves, consider implementing a preventive maintenance schedule. This includes periodic checks for leaks, ensuring that the actuators are working correctly, and cleaning any contaminants that may block flow paths. Keeping a log of performance metrics can also help track any changes in system behavior, allowing for timely interventions when necessary.

How Flow Control Valves Improve System Efficiency and Reliability

Flow control valves play a pivotal role in enhancing the efficiency and reliability of fluid systems across various industries. By precisely regulating the flow rate and pressure of fluids, these valves ensure that systems operate within optimal parameters. This precise control minimizes energy wastage, reduces operational costs, and prolongs the lifespan of equipment by preventing overpressure and cavitation. As a result, flow control valves contribute significantly to the overall performance of hydraulic and pneumatic systems.

Moreover, the use of flow control valves enhances system reliability by providing consistent operation under varying conditions. They allow for adjustments in real-time, enabling systems to adapt to changes in demand without compromising performance. This adaptability not only prevents system failures but also makes maintenance more manageable. Regular monitoring and control of fluid flow improve safety, reduce the risk of leaks, and ensure compliance with operational standards, making flow control valves essential components for maintaining system integrity and efficiency.

Why Flow Control Valve is Essential for Effective System Performance

| Feature | Description | Impact on System | Efficiency Gain (%) | Reliability Rating |

|---|---|---|---|---|

| Pressure Regulation | Maintains consistent pressure levels in the system. | Prevents pressure spikes that can lead to system failures. | 25% | High |

| Flow Regulation | Controls the flow rate through the system. | Ensures optimal operation of downstream components. | 20% | Medium |

| Temperature Control | Regulates temperature within the system. | Reduces wear and tear on mechanical components. | 15% | High |

| Energy Savings | Reduces energy consumption by optimizing flow. | Decreases operational costs significantly. | 30% | Very High |

| Maintenance Alerts | Provides notifications for maintenance needs. | Improves overall system reliability and lifespan. | N/A | Medium |

Common Applications of Flow Control Valves in Various Industries

Flow control valves play a crucial role in various industries by regulating the flow and pressure of fluids within systems. In the manufacturing sector, these valves are often employed in hydraulic and pneumatic systems to ensure optimal performance and efficiency. By maintaining precise flow rates, manufacturers can enhance production capabilities and reduce waste, ultimately leading to improved operational reliability.

In the water management industry, flow control valves are vital for regulating the distribution of water in pipelines and treatment facilities. They help manage pressure levels and prevent backflow, ensuring that clean water reaches residential and commercial areas without interruption.

Additionally, flow control valves are essential in the HVAC industry, where they are used to adjust the flow of air and refrigerants. This adjustment helps maintain comfortable indoor environments while optimizing energy consumption, contributing to sustainability efforts in building management.

Challenges and Considerations in Selecting Flow Control Valves for Systems

When selecting flow control valves for any system, several challenges and considerations must be taken into account to ensure optimal performance. One of the primary challenges is determining the appropriate size and type of valve needed. An improperly sized valve can result in inefficient flow rates or pressure drops, ultimately leading to system malfunctions. It's crucial to assess the specific requirements of the system, including the medium being controlled, the flow rate, and the pressure conditions involved.

Another significant consideration is the material of the valve. Depending on the system's application—be it water, oil, or chemicals—the materials that make up the valve must be compatible with the medium to prevent corrosion and ensure durability. Additionally, working conditions such as temperature and pressure must align with the valve's specifications. It's advisable to consult with experts or detailed manuals before making a decision on the valve materials.

Tips: When selecting a flow control valve, always perform a thorough analysis of your system’s requirements. Also, consider seeking advice from experienced professionals in the field, as their insights can help you avoid common pitfalls and optimize your system's performance. Regular maintenance checks can also prolong the lifespan of the valve and prevent costly downtime.

Flow Control Valve Performance Metrics

This chart illustrates the impact of different flow control valve types on system performance across various parameters such as efficiency, pressure drop, and cost. Selecting the right valve is crucial for optimal system performance.

Related Posts

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Unlocking Efficiency: The Vital Role of Hydraulic Pressure Relief Valves in Industrial Systems

-

What is a Pilot Operated Check Valve and How Does It Work in Hydraulic Systems

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance

-

Understanding the Role of Check Valves in Modern Industrial Systems

-

2025 Top 5 Proportional Valves to Enhance Your Industrial Efficiency