- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

The Future of Automation: How Servo Valves are Revolutionizing Industry Efficiency

The rapid advancement of automation technology is reshaping industries across the globe, with servo valves emerging as a key component driving this transformation. According to a recent report by Markets and Markets, the global servo valve market is projected to reach $8.18 billion by 2026, growing at a CAGR of 7.3% from 2021. This growth underscores the increasing reliance on precision control and efficiency in industrial applications, where servo valves play a critical role in regulating fluid flow and motion.

By providing superior performance in terms of responsiveness and accuracy, servo valves enhance system reliability and productivity. As industries strive for optimization and increased efficiency, the integration of servo valves within automation systems is set to revolutionize processes, reduce operational costs, and improve overall output. The drive towards more intelligent and agile manufacturing solutions positions servo valves as essential tools in the future landscape of industrial automation.

Table of Contents

[Hide]

The Evolution of Servo Valves in Industrial Automation

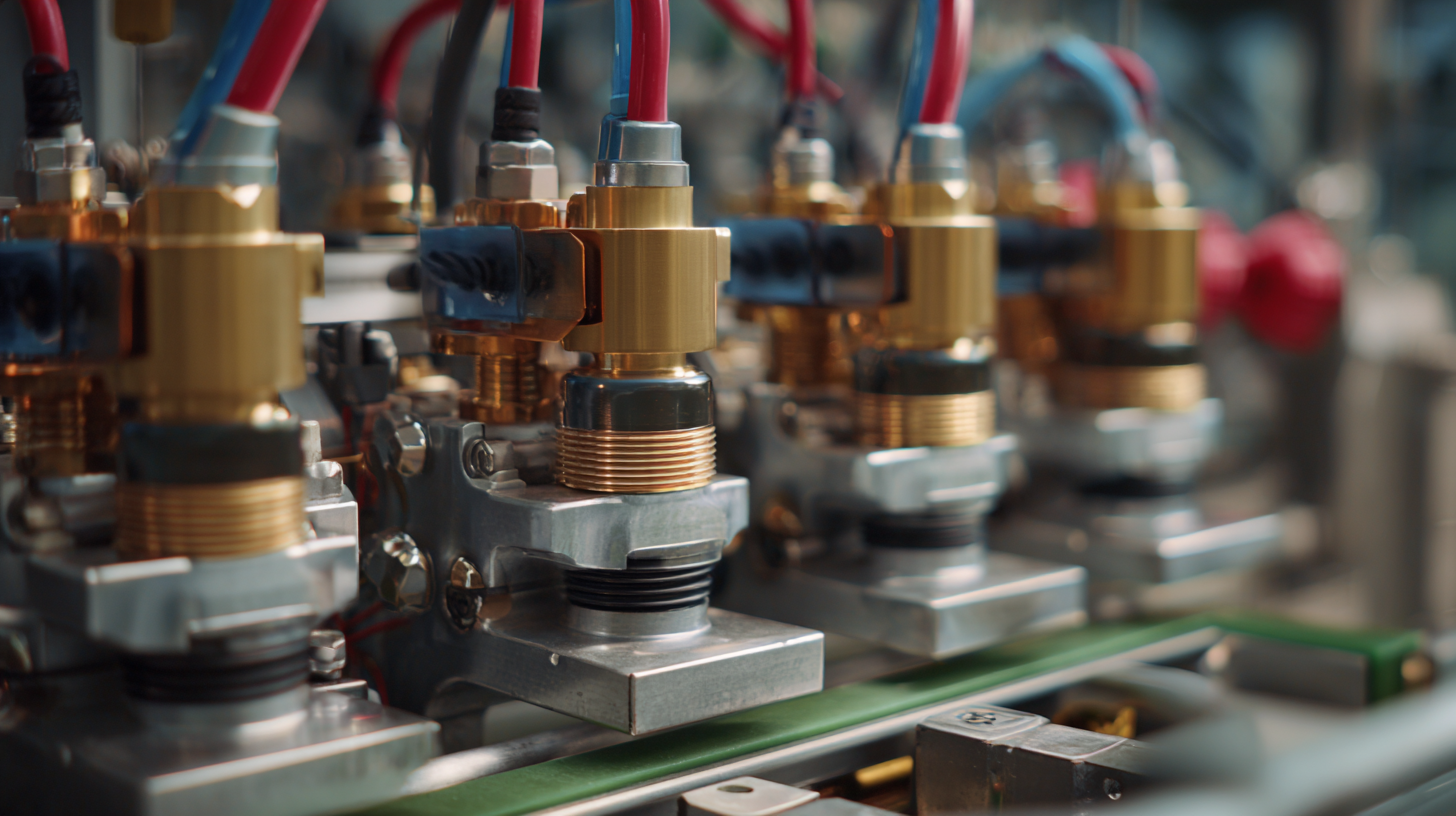

The evolution of servo valves has played a pivotal role in transforming industrial automation. Initially, servo valves operated on simple hydraulic principles, implementing basic feedback mechanisms to control fluid flow and pressure. As technology progressed, these devices became more sophisticated, incorporating digital electronics that enhanced responsiveness and precision. This transition not only improved operational reliability but also facilitated more complex automation tasks, allowing industries to streamline their workflows significantly.

In recent years, the rise of smart manufacturing has further accelerated the development of servo valve technology. Advanced algorithms and machine learning capabilities now enable these valves to self-optimize in real-time, responding adaptively to changing operational conditions. This integration with IoT (Internet of Things) frameworks allows for predictive maintenance and greater energy efficiency, ensuring that machinery operates at peak performance with minimal downtime. As servo valves continue to evolve, they are set to become even more integral to the future of automated industrial processes, driving efficiency and innovation across various sectors.

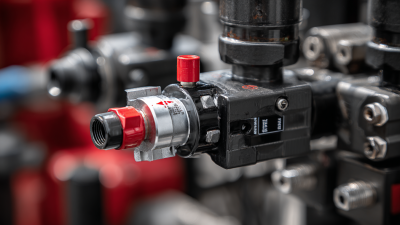

Key Benefits of Implementing Servo Valves for Efficiency Gains

The implementation of servo valves in various industrial applications is significantly enhancing operational efficiency. These advanced control devices allow for precise regulation of fluid flow, enabling manufacturers to achieve optimal performance from their machinery. One of the key benefits of servo valves is their rapid response time, which allows systems to adjust quickly to changing conditions. This capability minimizes downtime and maximizes productivity, as processes can be fine-tuned in real time to meet demand fluctuations.

Moreover, servo valves are instrumental in reducing energy consumption and waste. Their ability to provide accurate control means that energy usage can be optimized, leading to lower operational costs. By ensuring that machines only use the necessary amount of energy, businesses can not only save on utility bills but also reduce their environmental footprint. This shift towards smarter, more efficient operation via servo valves is setting a new standard in industry, fostering a culture of sustainability while improving overall productivity.

Comparative Analysis: Servo Valves vs. Traditional Control Methods

In the realm of industrial automation, servo valves are proving to be a game-changer compared to traditional control methods. Traditional hydraulic and pneumatic systems often rely on on-off valves, which can lead to inefficiencies and jerky movements. These systems lack the precision needed for modern applications, frequently resulting in increased wear and reduced operational lifespan. In contrast, servo valves allow for fine control of fluid flow and pressure, enabling smoother and more responsive system behavior. This precision not only enhances the overall performance but also minimizes the energy consumption associated with excessive cycling of equipment.

Furthermore, the adoption of servo valves translates into significant improvements in productivity. Unlike conventional control methods that may require longer response times to process changes in setpoints, servo valves can react almost instantaneously. This capability empowers industries to implement more complex automation scenarios, such as adaptive control in response to variable production demands. As manufacturers strive to remain competitive, integrating servo technology emerges as a vital strategy to streamline operations and enhance output, making it clear that the future of industrial efficiency is closely tied to the evolution of control mechanisms.

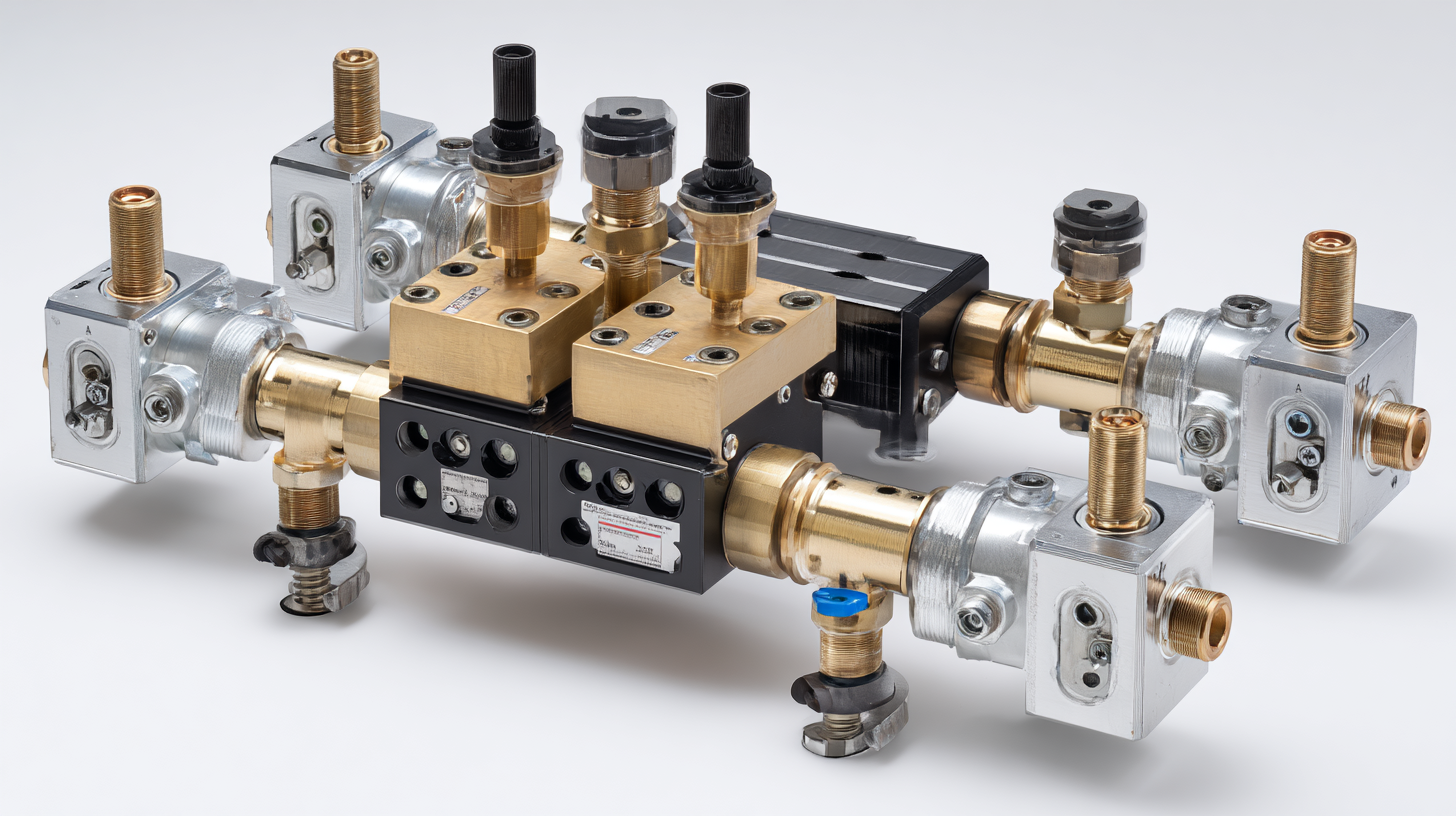

Real-World Applications of Servo Valves in Various Industries

Servo valves are rapidly transforming industrial operations across various sectors by enhancing efficiency and precision. In the automotive industry, for example, servo valves facilitate advanced automation in assembly lines, enabling precise control of hydraulic systems. This leads to faster production rates and improved product quality, significantly reducing waste. Similarly, in the aerospace sector, these valves are critical for flight control systems, ensuring smooth and accurate movements that are vital for safety and performance.

Tips: When considering the integration of servo valves in your operations, assess the specific needs of your production line. Investing in training for your team on the latest automation technologies will maximize the effectiveness of these systems.

In the energy sector, servo valves play a crucial role in optimizing the operation of renewable energy systems, such as wind turbines and solar power setups. Their ability to adjust pressure and flow dynamically helps improve energy conversion efficiency and reduce operational costs. Additionally, in the pharmaceutical industry, servo valves ensure precise fluid handling during manufacturing processes, which is essential for compliance with stringent quality standards.

Tips: Regular maintenance and monitoring of servo valve systems can prevent costly downtimes and enhance reliability. Consider implementing a predictive maintenance strategy to anticipate issues before they disrupt operations.

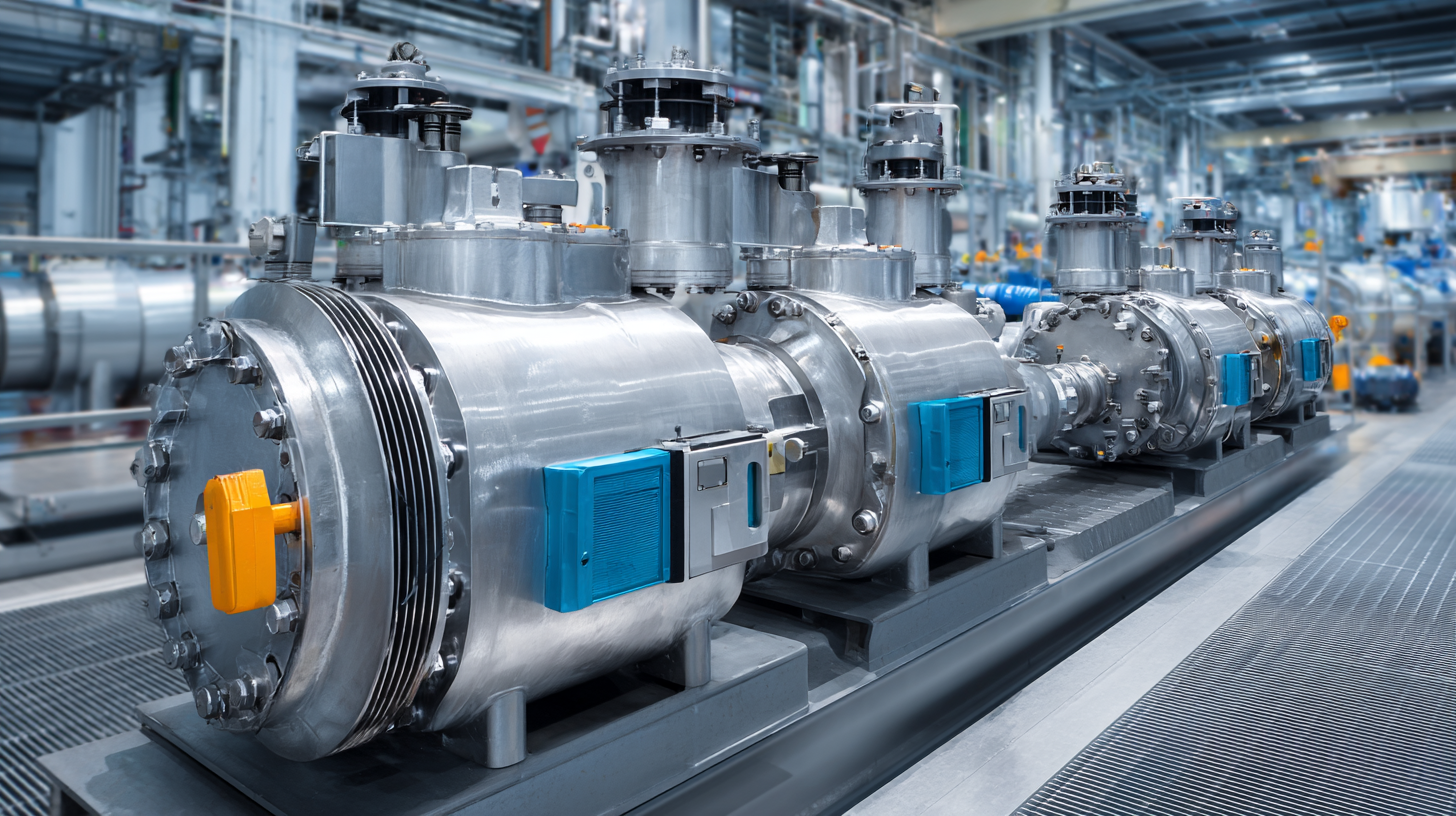

Future Trends: Innovations in Servo Valve Technology and Automation

In recent years, innovations in servo valve technology have significantly enhanced automation processes across various industries. Modern servo valves feature improved precision and responsiveness, allowing for greater control over fluid movement and energy consumption. These advancements enable industries to optimize their operations, thereby minimizing waste and maximizing productivity. Moreover, the integration of smart technologies, such as IoT connectivity, is enabling real-time monitoring and predictive maintenance, further streamlining operations.

Another exciting trend in servo valve technology is the development of new materials and designs that enhance durability and performance. These innovations not only extend the lifespan of the valves but also improve their efficiency under varying operational conditions. With the rise of artificial intelligence in automation systems, servo valves are becoming increasingly intelligent, adapting to changing conditions and learning from previous operations to enhance adaptability and decision-making processes. As these technologies evolve, they are poised to reshape industrial automation, driving unprecedented levels of efficiency and effectiveness.

The Future of Automation: How Servo Valves are Revolutionizing Industry Efficiency

| Dimension | Current Value | Future Trend | Impact on Industry |

|---|---|---|---|

| Response Time | 10 ms | Under 5 ms | Greater Precision and Control |

| Energy Efficiency | 75% | 90%+ | Reduced Operational Costs |

| Integration Level | 70% | 95% | Seamless Automation |

| Smart Features | Basic | Advanced AI Capabilities | Enhanced Decision Making |

| Maintenance Frequency | 6 Months | 12 Months+ | Lower Downtime |

Related Posts

-

Unlocking Efficiency: The Vital Role of Hydraulic Pressure Relief Valves in Industrial Systems

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

The Essential Guide to Understanding Pressure Relief Valves: Safety and Function Explained

-

Maximizing Efficiency: How Directional Control Valves Transform Hydraulic Systems

-

Exploring Innovative Control Products: Transforming Industries with Smart Technology