- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Top Hydraulic Unit Trends to Watch in 2025 for Optimal Performance

In the evolving landscape of industrial applications, hydraulic units continue to play a pivotal role in enhancing operational efficiency and performance. As we look towards 2025, several trends are emerging that promise to redefine the capabilities and functionalities of hydraulic units across various sectors. Engaging with these trends not only allows businesses to stay ahead of the curve but also optimizes the overall performance of their hydraulic systems.

The integration of advanced technologies, such as IoT and AI, is significantly transforming how hydraulic units operate, leading to smarter, more responsive systems. Furthermore, a growing emphasis on sustainability is driving innovations in hydraulic unit design and operation, which focus on reducing energy consumption while maintaining peak performance. By understanding and adapting to these trends, companies can enhance their equipment's reliability and efficiency, ultimately resulting in better service delivery and cost savings. The coming years will prove crucial for those looking to harness the full potential of hydraulic units in their operations, making it essential for industry stakeholders to stay informed and proactive.

Table of Contents

[Hide]

Emerging Technologies in Hydraulic Units for Enhanced Efficiency

As the hydraulic unit industry evolves, emerging technologies continue to enhance efficiency and performance. One notable trend is the integration of IoT (Internet of Things) capabilities into hydraulic systems, allowing for real-time data monitoring and predictive maintenance. According to a recent report by Market Research Future, the IoT-enabled hydraulic systems are projected to substantially increase operational efficiency, reducing downtime by up to 25%. This shift towards smart hydraulics not only minimizes maintenance costs but also maximizes productivity across various applications.

Another significant development is the adoption of advanced materials such as lightweight composites and high-strength alloys in hydraulic unit manufacturing. The utilization of these materials can lead to significant weight reductions, improving fuel efficiency and overall system performance. Data from the International Journal of Engineering Research shows that hydraulic units built with these innovative materials can achieve up to a 15% increase in performance metrics compared to traditional designs.

Tips: When considering upgrades or new installations of hydraulic units, focus on IoT integration capabilities to leverage real-time data analytics. Moreover, investing in advanced materials can dramatically enhance the longevity and efficiency of systems. Regularly reviewing the latest industry reports can also help in making informed decisions about technology trends and innovations that may impact performance.

Top Hydraulic Unit Trends to Watch in 2025 for Optimal Performance

| Trend | Description | Impact on Efficiency | Projected Growth (2025) |

|---|---|---|---|

| Smart Sensors | Integration of IoT sensors for real-time monitoring and data analysis. | Significantly reduces downtime and enhances system responsiveness. | 30% increase in demand. |

| Eco-Friendly Fluids | Adoption of biodegradable hydraulic fluids to reduce environmental impact. | Improves sustainability ratings and compliance with regulations. | 25% increase in market adoption. |

| Electric Actuation | Shift from traditional hydraulic systems to electric actuation technologies. | Enhances precision and reduces energy consumption. | 40% growth in related modules. |

| Modular Design | Development of modular hydraulic units for easier maintenance and scalability. | Increases adaptability and reduces maintenance costs. | 35% increase in demand. |

| Advanced Simulation Tools | Utilization of simulation software for hydraulic system design optimization. | Boosts design efficiency and reduces prototype costs. | 20% increase in usage. |

Sustainability Practices in Hydraulic Unit Design and Manufacturing

The growing emphasis on sustainability in hydraulic unit design and manufacturing reflects a significant shift in the industry towards eco-friendly practices. According to a report by the Hydraulic Institute, approximately 70% of manufacturers are increasingly investing in sustainable technologies to enhance efficiency and reduce the environmental impact of their hydraulic units. This trend is driven by both regulatory pressures and consumer demand for greener solutions. The adoption of environmentally friendly hydraulic fluids, which can reduce energy consumption by up to 20%, is one such practice that manufacturers are now prioritizing.

Additionally, modern design approaches, including the implementation of life cycle assessments, are allowing companies to evaluate the environmental impact of hydraulic units from production to disposal. Implementing modular designs not only extends the lifespan of hydraulic systems but also simplifies repairs and upgrades, ultimately minimizing waste. According to a recent study by the International Fluid Power Society, up to 30% of hydraulic unit waste can be reduced through more sustainable manufacturing practices, indicating a clear advantage in both cost savings and environmental stewardship. As we approach 2025, the integration of sustainability into hydraulic unit design will be a critical factor for industry leaders aiming to optimize performance while addressing global environmental challenges.

Advancements in Digital Monitoring and Control Systems

The landscape of hydraulic unit technology is rapidly evolving, particularly with the integration of advanced digital monitoring and control systems. As the industry moves towards greater efficiency and precision, these innovations are providing operators with real-time data and analytics, transforming how hydraulic systems are managed. Enhanced sensor technology enables the continuous monitoring of performance metrics such as pressure, temperature, and flow rates, allowing for proactive maintenance and minimizing downtime.

Moreover, the implementation of sophisticated control algorithms is optimizing hydraulic functions, leading to improved responsiveness and energy efficiency. Automation and smart technologies facilitate seamless integration with existing systems, empowering users to analyze patterns and make data-driven decisions. This shift not only enhances operational reliability but also significantly reduces the environmental impact of hydraulic processes by ensuring that systems run at their peak performance without unnecessary waste.

The future of hydraulic units will undoubtedly be shaped by these advancements, marking a new era of innovation in the industry.

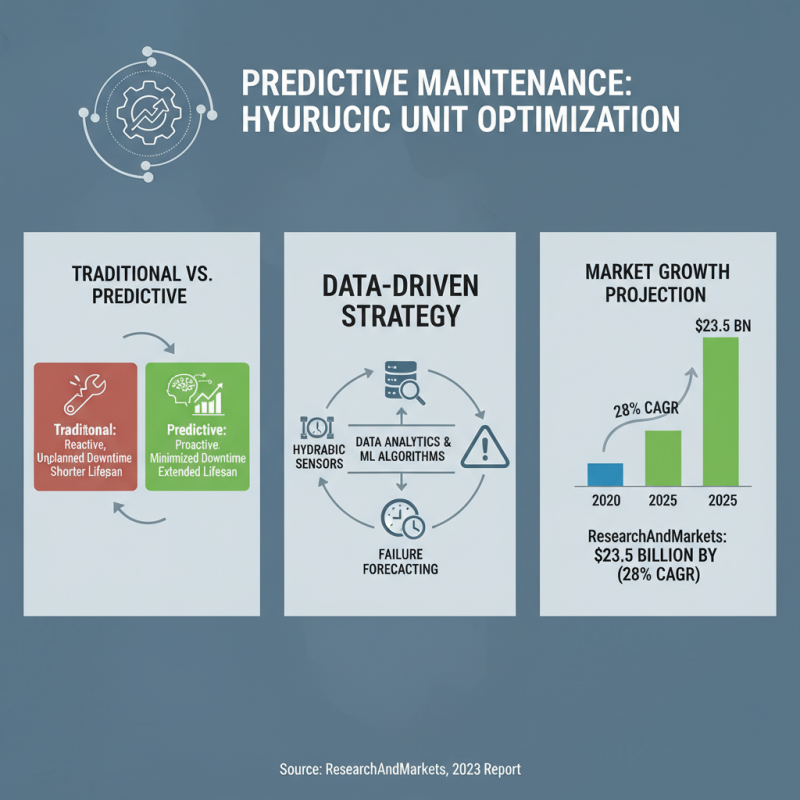

The Role of Predictive Maintenance in Hydraulic Unit Performance

Predictive maintenance is emerging as a pivotal element in enhancing the performance of hydraulic units, particularly as industries increasingly lean towards data-driven strategies. By utilizing advanced data analytics and machine learning algorithms, predictive maintenance enables operators to foresee potential failures before they occur. According to a report by ResearchAndMarkets, the predictive maintenance market is projected to reach $23.5 billion by 2025, growing at a CAGR of 28% from 2020. This trend is not just a reaction to existing challenges but a proactive approach that taps into the rich data generated by hydraulic systems to optimize performance and extend equipment lifespan.

The application of predictive maintenance in hydraulic units involves continuous monitoring of system parameters, such as pressure, temperature, and vibration. This real-time data can reveal patterns and anomalies that indicate wear or impending failure. A study by the International Journal of Engineering and Technology estimates that predictive maintenance can reduce downtime by up to 25%, significantly lowering operational costs. Additionally, by minimizing unexpected failures, companies can enhance overall productivity and maintain smoother operations. The integration of IoT technology further supports this trend, as connected devices provide seamless data collection and analysis, empowering organizations to implement predictive strategies effectively.

Key Market Players and Innovations Shaping the Future of Hydraulics

The hydraulic unit industry is undergoing rapid transformation, driven by significant innovations and the strategic maneuvers of key market players. Leading companies are increasingly focusing on enhancing the efficiency and reliability of hydraulic systems through advanced materials and cutting-edge technologies. Developments such as smart sensors and IoT integration are not only improving operational performance but also enabling predictive maintenance, thereby reducing downtime and operational costs.

Moreover, sustainability is becoming a pivotal theme in the hydraulic sector, with many firms investing in eco-friendly hydraulic fluids and energy-efficient systems. This shift aligns with global environmental goals and meets the rising demand for greener industrial solutions. As these players continue to innovate, we can expect a push toward more compact, lightweight designs that offer superior performance without compromising safety or reliability. These trends are poised to redefine the hydraulics landscape, enhancing productivity across industries reliant on hydraulic technology.

Top Hydraulic Unit Trends to Watch in 2025

This chart illustrates the projected growth trends of various hydraulic unit innovations expected to impact optimal performance in 2025. The data highlights the focus areas of hydraulic technology development, including energy efficiency, automation, and digital integration.

Related Posts

-

How to Choose the Right Hydraulic Unit for Your Industrial Needs

-

The Essential Guide to Understanding Hydraulic Power Packs in Industrial Applications

-

10 Essential Tips for Maintaining an Efficient Hydraulic System

-

2025 Top 10 Check Valves Trends Innovations and Market Statistics

-

Understanding the Role of Check Valves in Modern Industrial Systems

-

Exploring Innovative Control Products: Transforming Industries with Smart Technology