- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Maximizing Efficiency: How Directional Control Valves Transform Hydraulic Systems

In the realm of hydraulic systems, the role of a directional control valve is pivotal in maximizing efficiency and enhancing overall performance. These valves serve as the brains behind the hydraulic circuits, regulating the flow of fluid in a controlled manner to ensure that machinery operates smoothly and effectively. Understanding how to optimize the use of directional control valves can lead to improved operational results, reduced energy consumption, and minimized wear and tear on system components.

This guide aims to elucidate the various features and functionalities of directional control valves, highlighting best practices for their implementation in hydraulic systems. By mastering the operation of these essential components, engineers and technicians can unlock the full potential of their hydraulic systems, driving innovation and productivity in various industrial applications.

Table of Contents

[Hide]

Defining Directional Control Valves: Types and Applications in Hydraulic Systems

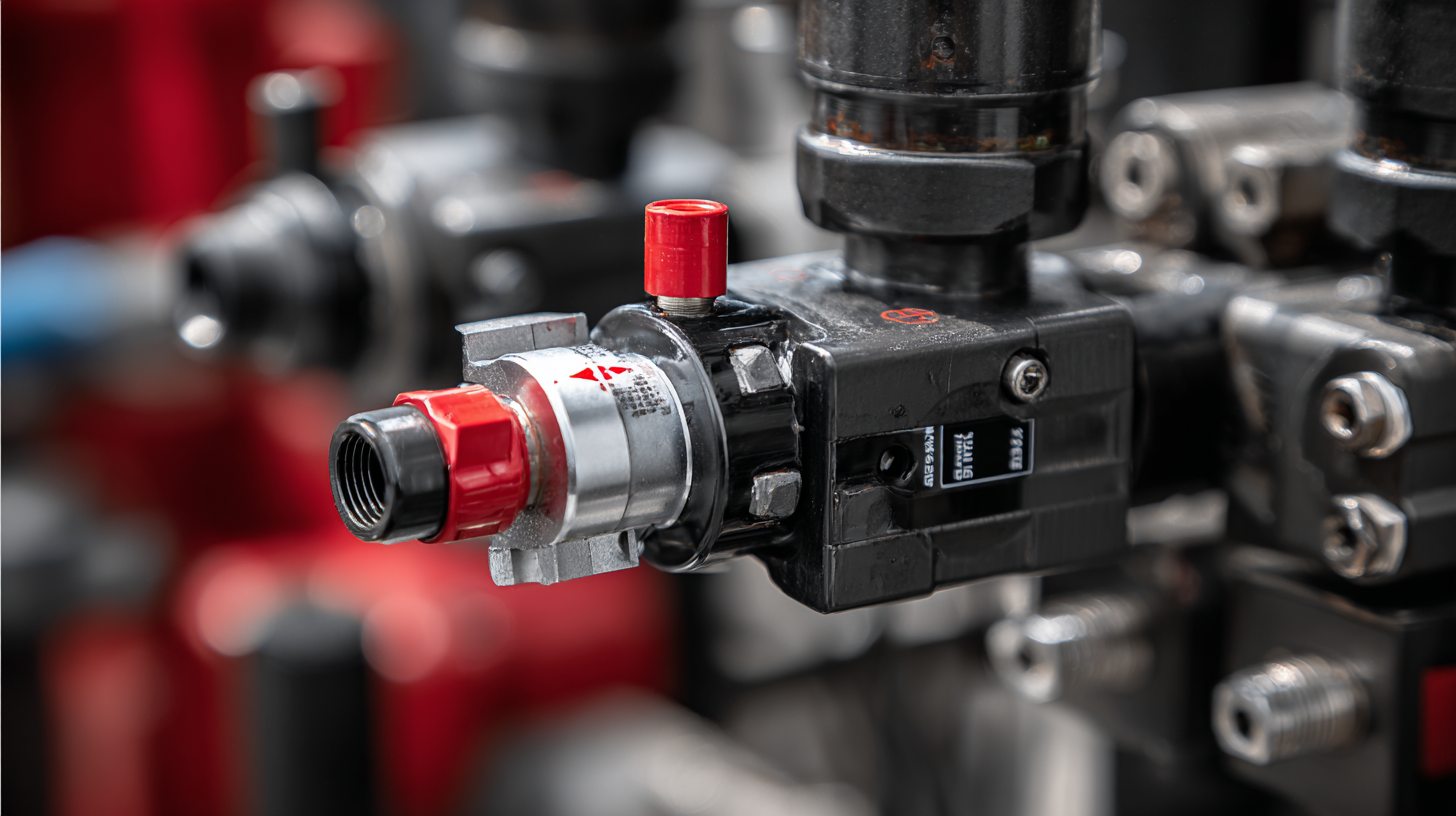

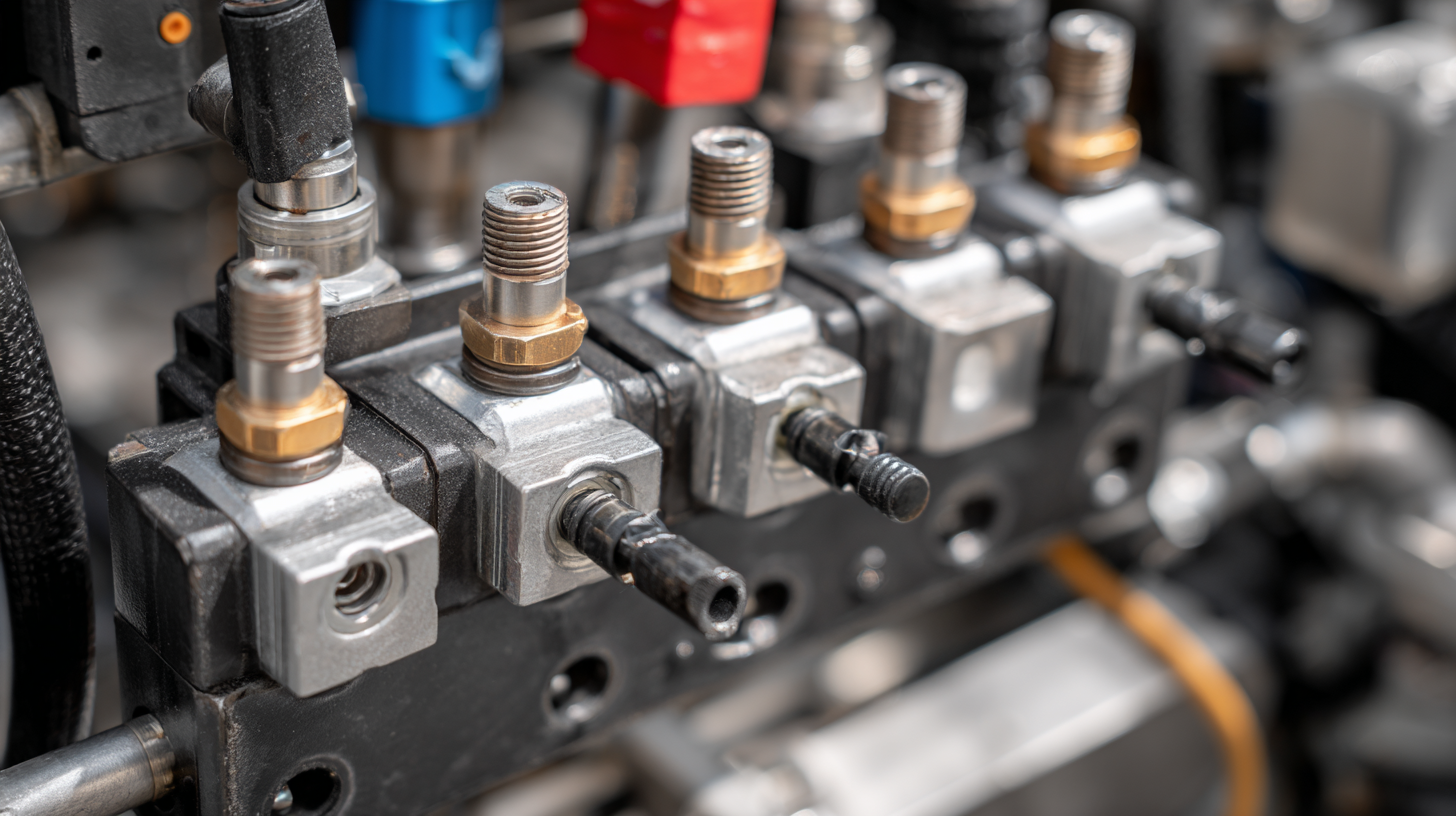

Directional control valves are essential components in hydraulic systems, facilitating the precise control of fluid flow direction. These valves can be categorized into various types based on their design and functionality, including spool valves, poppet valves, and rotary valves.

Spool valves, often used in mobile equipment and industrial machines, allow for multiple flow paths and can control the movement of actuators or motors by moving a spool within a cylinder. Poppet valves, on the other hand, are commonly employed in applications requiring simple on-off control, offering quick operation for tasks like clamping or lifting.

Directional control valves are essential components in hydraulic systems, facilitating the precise control of fluid flow direction. These valves can be categorized into various types based on their design and functionality, including spool valves, poppet valves, and rotary valves.

Spool valves, often used in mobile equipment and industrial machines, allow for multiple flow paths and can control the movement of actuators or motors by moving a spool within a cylinder. Poppet valves, on the other hand, are commonly employed in applications requiring simple on-off control, offering quick operation for tasks like clamping or lifting.

The applications of directional control valves extend across numerous industries, from automotive to manufacturing. In automotive hydraulic systems, these valves manage brake actuators, enhancing safety and responsiveness. Similarly, in manufacturing, they regulate fluid flow in machinery, enabling automated processes and improving overall efficiency. By selecting the appropriate type of directional control valve, engineers can optimize hydraulic system performance, ensuring reliable operation tailored to specific application requirements.

The Role of Directional Control Valves in Enhancing Hydraulic System Performance

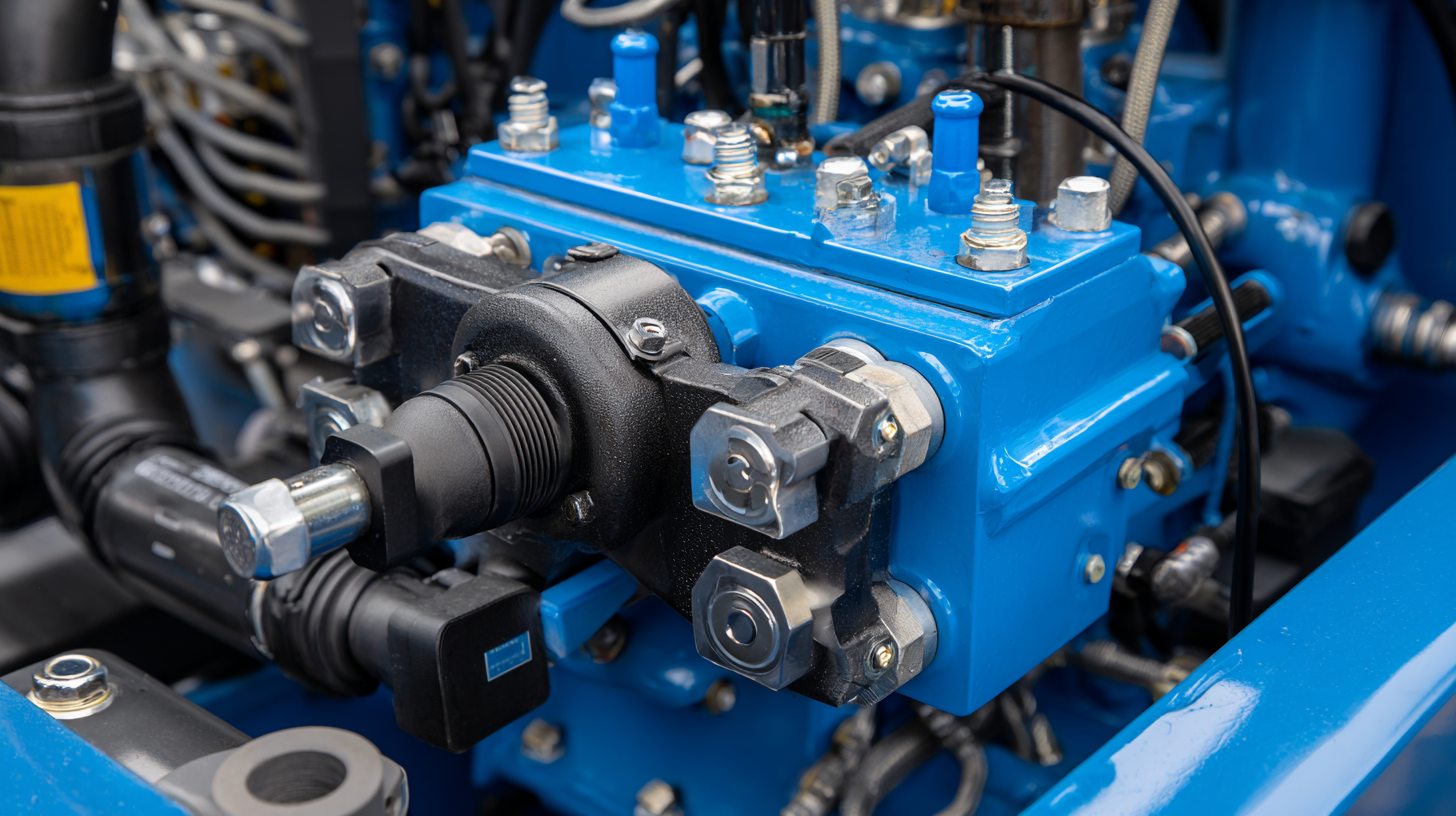

Directional control valves are pivotal components in hydraulic systems, playing a crucial role in directing fluid flow and ensuring optimal performance. According to a report by Research and Markets, the global hydraulic valve market is expected to reach $11.22 billion by 2025, driven largely by advancements in hydraulic technology and the increasing demand for efficient systems across various industries. By managing the flow paths of hydraulic fluids with precision, these valves enhance the performance, reliability, and energy efficiency of hydraulic applications.

The functionality of directional control valves directly impacts system efficiency, given that they minimize pressure losses and improve response times. The International Journal of Hydraulic Engineering highlights that modern valves with high flow rates and reduced leakages can lead to energy savings of up to 30%. This efficiency not only lowers operational costs but also contributes to the sustainability goals of industries by reducing overall energy consumption. As hydraulic systems continue to evolve, the implementation of advanced directional control valves will be integral to maximizing performance and enhancing the capabilities of modern machinery.

Maximizing Efficiency: Directional Control Valves in Hydraulic Systems

This chart illustrates the influence of directional control valves on various performance indicators of hydraulic systems, including flow rate, pressure drop, response time, energy efficiency, and system cost. Maximizing these parameters can significantly enhance the overall efficiency of hydraulic systems.

Industry Statistics: Efficiency Gains from Implementing Directional Control Valves

Directional control valves play a pivotal role in enhancing efficiency within hydraulic systems. According to industry statistics, the implementation of these valves can lead to efficiency gains of up to 30%. By precisely directing fluid flow in hydraulic circuits, these valves minimize energy loss and streamline operations, which is essential for industries such as manufacturing, construction, and agriculture. Their design flexibility allows them to be tailored for specific applications, further optimizing performance and reducing operational costs.

Moreover, the reliability of directional control valves contributes significantly to overall system performance. Studies show that companies integrating advanced control valves not only experience lower downtime due to fewer mechanical failures but also report improved response times in their systems. As industries continue to pursue automation and efficiency, the adoption of directional control valves becomes increasingly vital, establishing them as a cornerstone technology in modern hydraulic solutions.

Case Studies: Directional Control Valves Transforming Industrial Hydraulic Solutions

Directional control valves play a pivotal role in modern hydraulic systems, effectively managing the flow and direction of hydraulic fluid to enhance efficiency across various industrial applications. According to a report by MarketsandMarkets, the global hydraulic valve market is projected to reach USD 30.32 billion by 2026, with directional control valves being a crucial component driving this growth. In manufacturing environments, these valves are utilized to automate the movement of machinery, leading to increased precision and reduced operational downtime.

In case studies featuring the automotive and aerospace industries, the implementation of advanced directional control valves has resulted in significant performance improvements. For instance, a leading automotive manufacturer reported a 20% increase in assembly line efficiency after integrating proportional directional control valves into their hydraulic systems. These valves allowed for more responsive adjustments to the flow, enabling rapid cycle times and better control of actuator movements. Similarly, in aerospace applications, the adoption of these valves has contributed to enhanced safety and reliability, ensuring precise control of hydraulic functions critical to various aircraft operations. The transformative impact of directional control valves is evident, underscoring their essential role in modern industrial hydraulic solutions.

Future Trends: Innovations in Directional Control Valve Technology and their Impact on Efficiency

Directional control valves are pivotal in enhancing the efficiency of hydraulic systems by enabling precise control over fluid flow and pressure. Recent innovations in directional control valve technology focus on integrating electronic and digital systems to optimize performance. According to a recent report by MarketsandMarkets, the global directional control valve market is projected to reach $8.3 billion by 2025, driven by increased demand for automation and energy-efficient solutions across various industries.

Emerging technologies such as smart valves with IoT capabilities are set to revolutionize hydraulic applications. These advanced valves not only allow for remote monitoring and control but also provide real-time data analytics, leading to better decision-making and maintenance practices. A study by ResearchAndMarkets indicates that the adoption of smart valve technology can enhance efficiency by up to 30%, significantly reducing energy consumption and operational costs in hydraulic systems. As industries continue to prioritize sustainability, the advancements in directional control valve technology will play a crucial role in achieving greater operational efficiencies and reducing environmental impact.

| Feature | Current Technology | Future Innovations | Impact on Efficiency |

|---|---|---|---|

| Flow Control | Manual valves | Electro-hydraulic control | Increased precision and response times |

| Energy Consumption | Standard hydraulic pumps | Variable speed drives | Reduction in energy usage by up to 30% |

| Diagnostics | Basic monitoring | IoT-enabled valves | Real-time data for predictive maintenance |

| Size and Weight | Standard size valves | Compact smart valves | Improved space-saving in design |

| Installation | Complex hydraulic systems | Modular valve solutions | Faster installation and lower labor costs |