- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Top 10 Benefits of Pilot Operated Check Valves in Industrial Applications

In the realm of industrial applications, optimizing fluid control systems is paramount for ensuring efficiency, safety, and reliability. One of the innovative solutions that has gained significant attention in this context is the pilot operated check valve. These valves play a crucial role in managing fluid flow, preventing backflow, and facilitating the seamless operation of various systems under pressure. Unlike traditional check valves, pilot operated check valves offer added flexibility and functionality, allowing for precise control over flow direction and shut-off.

As industries continue to evolve and demand more sophisticated fluid management solutions, understanding the benefits of pilot operated check valves becomes essential. From improved safety measures to enhanced energy efficiency, these valves contribute to the overall performance of industrial systems. In this article, we will explore the top 10 benefits of pilot operated check valves, highlighting their significance in creating robust and efficient fluid control mechanisms. By delving into their advantages, we aim to provide insights that can help industries make informed decisions in their fluid management strategies.

Table of Contents

[Hide]

Benefits of Enhanced Flow Control with Pilot Operated Check Valves

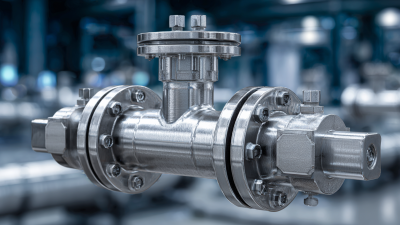

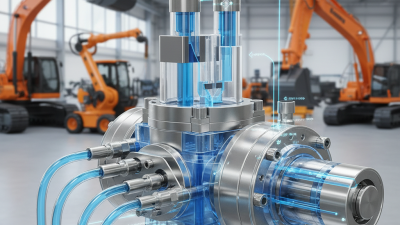

Pilot operated check valves (POCVs) play a crucial role in industrial applications by enhancing flow control, particularly in hydraulic systems. Unlike traditional check valves, which permit flow in one direction, pilot operated check valves combine features of both check and control valves. This design allows for precise control of flow rates, improving overall system efficiency. According to a report by the International Fluid Power Society, POCVs can reduce energy consumption by up to 30%, optimizing operational costs in industrial setups.

One key advantage of pilot operated check valves is their ability to maintain a constant flow under varying pressure conditions. This capability is essential in applications such as hydraulic presses and injection molding, where consistent pressure is necessary for quality output. Furthermore, POCVs improve system responsiveness by swiftly adapting to changes in flow requirements. Such performance is backed by research from the Hydraulic Institute, indicating that systems utilizing POCVs can achieve response time improvements of 15-25% compared to conventional valving solutions.

Tips: When implementing pilot operated check valves, it is crucial to select the appropriate sized valve for your application to ensure optimal performance. Also, regular maintenance can extend the lifespan of these valves, contributing to sustained efficiency in the long run. Consider consulting with an expert to tailor your system's needs effectively, leveraging the benefits of enhanced flow control.

Top 10 Benefits of Pilot Operated Check Valves in Industrial Applications

| Benefit | Description |

|---|---|

| Improved Flow Control | Allows for precise control of fluid flow in both directions. |

| Reduced Pressure Drops | Minimizes losses in the system, enhancing efficiency. |

| Leak Prevention | Helps to ensure no backflow occurs, protecting downstream equipment. |

| Compact Design | Space-saving design makes them suitable for various installations. |

| Enhanced Safety | Prevents accidents caused by unintended flow directions. |

| Versatile Applications | Suitable for a wide range of fluids, including gases and liquids. |

| Maintenance-Friendly | Designed for easy access, reducing downtime during servicing. |

| Extended Lifespan | Durable construction means longer operational life compared to traditional check valves. |

| Cost-Effective Solution | Reduces costs related to repair and fluid loss in industrial systems. |

| Better Control with Automation | Compatible with automated systems for enhanced control and efficiency. |

Reduction of Energy Consumption in Hydraulic Systems Using Check Valves

Pilot operated check valves are playing an increasingly vital role in enhancing the efficiency of hydraulic systems across various industrial applications. One of the most significant benefits of these valves is the notable reduction in energy consumption. According to a report from the Hydraulic Institute, systems employing pilot operated check valves can achieve energy savings of up to 30%, primarily by minimizing fluid leakage and ensuring optimal pressure management during operation. This reduction is critical as energy costs continue to rise, and industries seek ways to diminish their carbon footprints.

Additionally, the strategic design of pilot operated check valves allows for improved flow control, which further contributes to energy efficiency. Statistically, the Energy Efficiency Improvement Act reports that implementing advanced hydraulic components can lead to a 15% increase in overall system efficiency. In environments where hydraulic systems are extensively used, such as construction and manufacturing, the integration of these check valves not only improves operational performance but also significantly lowers operating costs. The synthesized energy savings and enhanced reliability ensure that industries can maintain competitive edges while promoting sustainable practices.

Top 10 Benefits of Pilot Operated Check Valves in Industrial Applications

This chart illustrates the key benefits of pilot operated check valves in industrial applications, highlighting their positive impacts on energy consumption and overall system performance.

Improved Safety Standards in Industrial Applications of Check Valves

In the realm of industrial applications, pilot operated check valves play a pivotal role in enhancing safety standards. These valves are designed to prevent backflow in hydraulic systems, ensuring that fluid only moves in the intended direction. According to a report by the International Society of Automation, improper backflow can lead to significant system failures and safety hazards, contributing to approximately 30% of industrial accidents. By implementing pilot operated check valves, industries can effectively mitigate these risks, promoting a safer working environment.

Furthermore, the enhanced control offered by pilot operated check valves allows for more precise operations in complex systems. This promotes not only safety but also efficiency, as these valves can handle high differential pressures without compromising system integrity. Data from the American Society of Mechanical Engineers suggest that systems employing these valves demonstrate a 15% increase in operational reliability, further supporting safety measures in the industrial sector.

**Tip:** When selecting pilot operated check valves, consider the specific pressure and flow conditions of your system to ensure optimal performance and safety.

The incorporation of pilot operated check valves is not just about compliance with safety regulations; it's also about fostering a culture of safety within organizations. With advancements in technology, these valves now come equipped with features that provide additional safety measures, such as automatic lock mechanisms and quick release functions. These innovations can significantly reduce the likelihood of accidents, ultimately enhancing the overall safety standards in industrial applications.

**Tip:** Regular maintenance and inspection of pilot operated check valves are essential to ensure they are functioning correctly and providing the intended safety benefits.

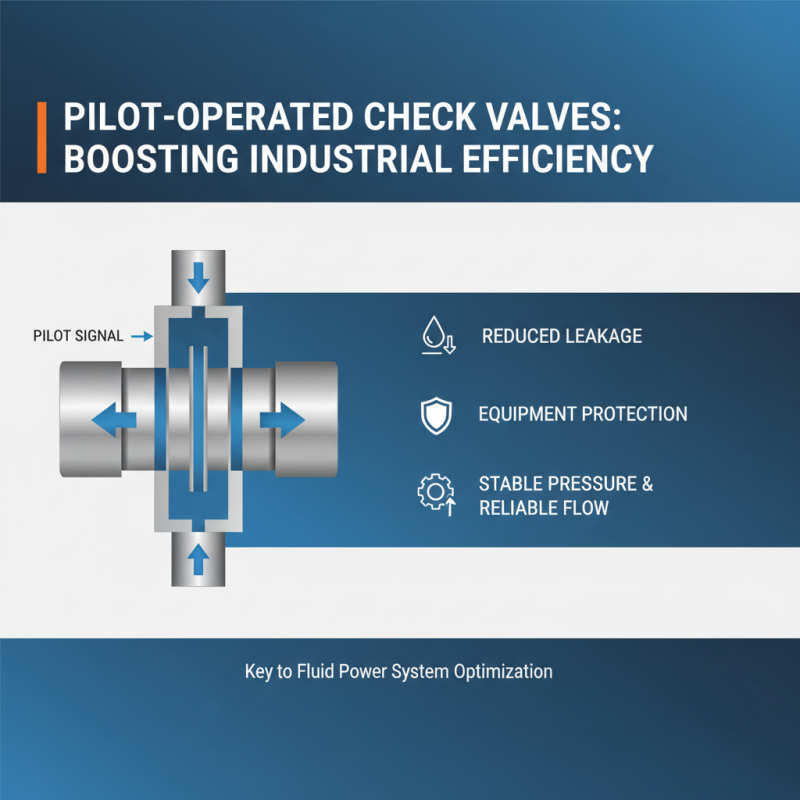

Increased Operational Efficiency Through Reduced Leakage Rates

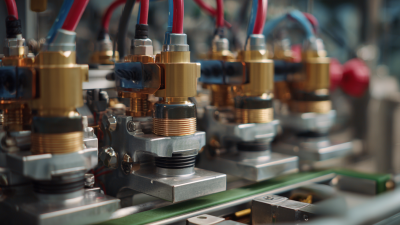

Pilot operated check valves have become a crucial component in industrial applications due to their ability to enhance operational efficiency through reduced leakage rates. By utilizing a pilot signal to control the valve's opening and closing, these valves minimize the risk of unintentional flow back, thus maintaining a stable system pressure. This design not only protects equipment from pressure surges and potential damage but also ensures that the fluid delivery remains consistent and reliable.

One effective way to maximize the benefits of pilot operated check valves is to properly size and select the right type for your application. Oversized or undersized valves can lead to inefficiencies and increased leakage. Regular maintenance and inspections also play a vital role in sustaining optimal performance. Operators should establish a routine maintenance schedule to check for wear and tear, ensuring that seals and moving parts are functioning correctly.

Tip: When selecting a pilot operated check valve, consider factors such as fluid viscosity and pressure conditions, as these can significantly influence valve performance and leakage rates. Another tip is to train personnel on the proper operational procedures and troubleshooting techniques to ensure that the system remains efficient and leak-free. By focusing on these aspects, industries can greatly benefit from the operational efficiency that pilot operated check valves provide.

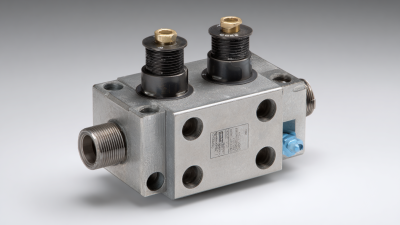

Versatility of Pilot Operated Check Valves in Various Industrial Settings

Pilot operated check valves have gained immense traction across various industrial settings, and their

versatility is one of the primary reasons for this

growing popularity. These valves are designed to prevent backflow while allowing controlled forward flow,

making them essential in hydraulics and fluid power applications. According to a

2022 report by the Global Valves Market Research, pilot

operated check valves are projected to witness a compound annual growth rate (CAGR) of 6.5%

over the next five years, reflecting their increasing adoption in sectors like

manufacturing, oil and gas, and construction.

Their adaptability extends beyond specific industries; pilot operated check valves are compatible with

a wide range of fluids, including water, oil, and various industrial chemicals. This feature makes them

suitable for applications such as hydraulic lifts, industrial pumps,

and even water treatment facilities. An industry study from the

International Society for Fluid Power indicated that

the efficiency of pilot operated check valves can improve system responsiveness by up to

30%, contributing to reduced operational costs and enhanced safety protocols in

industrial processes. This efficiency, combined with their ease of integration into existing systems,

positions them as a go-to solution in diverse industrial environments, further amplifying their

relevance in contemporary applications.

Related Posts

-

Understanding the Role of Check Valves in Modern Industrial Systems

-

What is a Pilot Operated Check Valve and How Does It Work in Hydraulic Systems

-

2025 Top 10 Check Valves Trends Innovations and Market Statistics

-

Top Trends in 2025 for Check Valves You Need to Know About

-

2025 Top Hydraulic Directional Valve Applications and Important Features to Know

-

The Future of Automation: How Servo Valves are Revolutionizing Industry Efficiency