- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

What is a Pilot Valve and How Does it Work for Fluid Control?

In the world of fluid control, the pilot valve plays a crucial role. John Smith, a leading expert in fluid dynamics, once stated, “A pilot valve is the heart of a fluid control system.” His insight captures the essence of this device.

A pilot valve acts as a signal transmitter. It controls larger valves using smaller amounts of fluid or pressure. This mechanism is essential in various industries, from manufacturing to aerospace. The efficiency of a pilot valve can significantly impact overall system performance.

However, it’s important to note that not all pilot valves are created equal. Some may be prone to failure under specific conditions. This raises questions about reliability and maintenance. A deeper understanding of pilot valves can lead to improved designs and better practices in fluid control systems. Addressing these challenges is vital for engineers to enhance operational efficiency.

Table of Contents

[Hide]

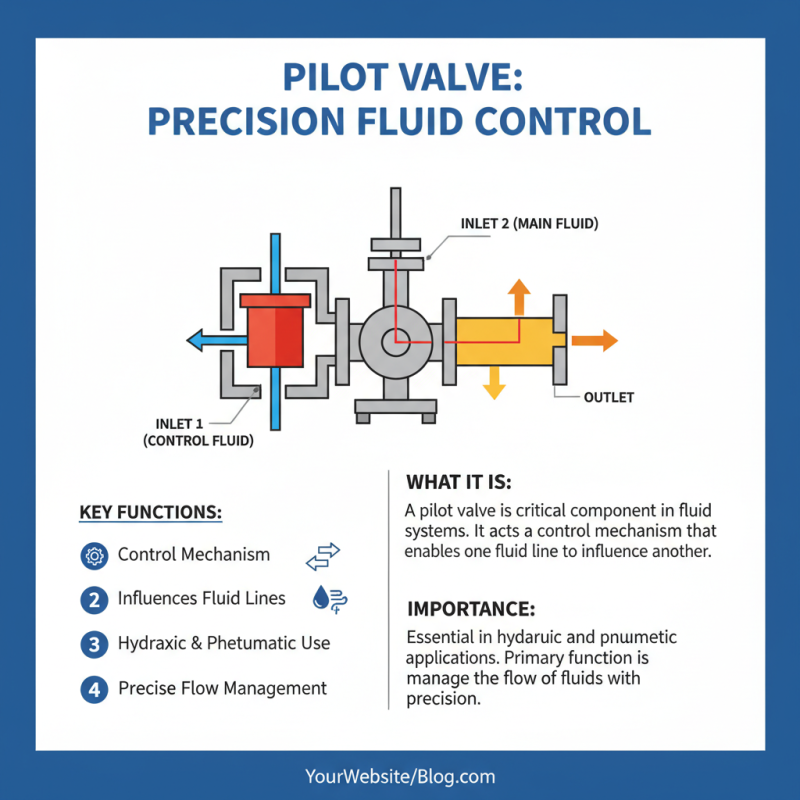

What is a Pilot Valve: Definition and Key Components

A pilot valve is a critical component in fluid control systems. It acts as a control mechanism that enables one fluid line to influence another. Pilot valves are essential in hydraulic and pneumatic applications. Their primary function is to manage the flow of fluids with precision.

Key components of a pilot valve include the actuator, body, and seat. The actuator generates the necessary movement to open or close the valve. The body houses the internal mechanisms. The seat creates a seal to prevent leaks. According to a 2022 report from Fluid Power Journal, pilot valves can improve system efficiency by up to 30%. This reduction in energy consumption is significant for industrial applications.

Despite their benefits, pilot valves come with challenges. Installation can be complex, and regular maintenance is crucial. Many users overlook this aspect, leading to failures or inefficiencies. It’s vital to choose the right materials for durability. In some cases, the wrong specifications can result in leaks or malfunctions. Thus, understanding these components is essential for effective fluid control.

Types of Pilot Valves Used in Fluid Control Systems

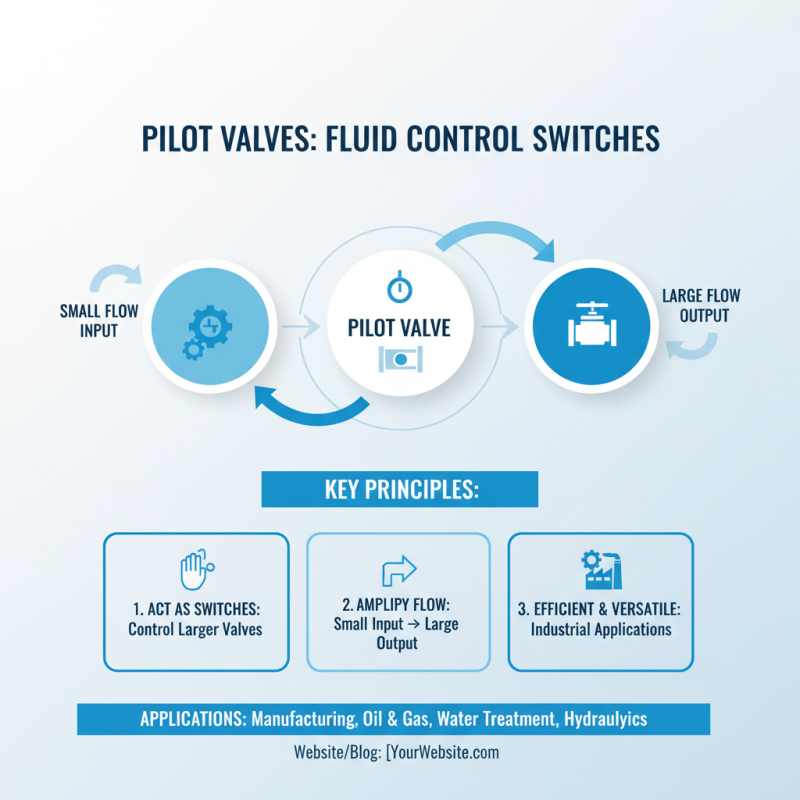

Pilot valves play a crucial role in fluid control systems. They act as miniature valves that control larger valves within a system. These valves rely on a small amount of fluid to open or close the larger valve. This helps regulate fluid flow effectively. There are several types of pilot valves, each suited for different applications.

Electro-pneumatic pilot valves use electrical signals to control their operation. They are often used in automated systems. Another common type is the hydraulic pilot valve, which uses hydraulic pressure to function. This allows for movements in heavy machinery. Proportional pilot valves adjust flow based on input signals, allowing for precise control.

Despite their importance, purchasing the right pilot valve can be complex. Not all systems are equal, and choosing the wrong type can lead to inefficiency. Proper installation and maintenance are also key. A poorly maintained pilot valve may not respond effectively. This could result in system failures, impacting overall performance. Understanding the specific needs of your fluid system is essential for optimal function.

Working Principle of Pilot Valves in Regulating Fluid Flow

Pilot valves are essential tools in fluid control systems. They regulate the flow of fluids by using a smaller pilot signal to control a larger valve. This design allows for efficient operation. When the pilot valve opens, it creates a pressure differential. This differential causes the main valve to either open or close, effectively controlling the flow.

The working principle of pilot valves hinges on their responsiveness. As the pilot signal changes, the valve reacts immediately. For instance, a slight increase in pressure from the pilot can result in a significant change in fluid flow. This amplification effect is crucial in many applications like hydraulic systems. The precision of the pilot valve plays a crucial role in the overall efficiency of the system.

However, there are challenges in using pilot valves. They can be sensitive to dirt and contaminants, which may hinder performance. Regular maintenance is necessary to ensure reliability. Moreover, improper installation can lead to leaks or inefficient operation. Reflecting on these aspects is important for anyone using pilot valves in their systems. Taking time to understand their functionality can prevent potential issues.

What is a Pilot Valve and How Does it Work for Fluid Control? - Working Principle of Pilot Valves in Regulating Fluid Flow

| Dimension | Value |

|---|---|

| Type of Valve | Pilot Valve |

| Function | Controls Fluid Flow |

| Working Pressure Range | 20 - 150 PSI |

| Fluid Types | Water, Oil, Air |

| Pilot Operated | Yes |

| Common Applications | Hydraulic Systems, Pneumatic Systems |

| Actuation Type | Electric, Pneumatic |

| Installation Orientation | Vertical, Horizontal |

Applications of Pilot Valves in Various Industries

Pilot valves play a crucial role in various industries. They act as switches to control larger valves and regulate fluid flow. These devices use a small flow to control a much larger flow. This makes them efficient and suitable for various applications.

In the manufacturing sector, pilot valves are vital for automation. They enable machines to operate smoothly and safely. For instance, a pilot valve can control hydraulic systems, allowing for precise movement of heavy machinery. This enhances productivity but requires careful setup. A miscalculated adjustment can lead to inefficiencies.

In the oil and gas industry, pilot valves ensure safe operation. They manage pressure and prevent leaks. However, they must be regularly maintained to function correctly. Even minor wear can affect their performance. Industries must prioritize training staff on proper usage and troubleshooting. This enhances safety and reliability in fluid control applications.

Performance Metrics and Standards for Pilot Valves in Fluid Control

Pilot valves play a crucial role in fluid control systems. Their performance metrics directly affect efficiency and safety. According to industry reports, a pilot valve's response time is critical. A typical response time ranges from 10 to 50 milliseconds. A faster response time can prevent fluid pressure fluctuations. It ensures stability, particularly in hydraulic systems.

Leakage rates are another important metric. Studies suggest that a good pilot valve has a leakage rate of less than 10 mL/min at full pressure. High leakage can lead to fluid wastage. It also compromises system performance. Piloting accuracy is paramount. An optimal pilot valve should maintain less than 2% deviation from setpoint pressure.

Standards for pilot valves include ISO 9001 and ANSI/ISA-75.01.01. These ensure reliability and quality in manufacturing. However, not all manufacturers meet these standards consistently. This inconsistency can cause issues in critical applications like aerospace or chemical processing. Regular testing against these standards is essential. Understanding these metrics helps in selecting the right pilot valve for specific applications. Fluid control systems rely on precise performance data to function properly.

Performance Metrics of Pilot Valves in Fluid Control

Related Posts

-

How to Choose the Right Directional Control Valve for Your Project

-

Understanding Pressure Control Valves: Types, Functions, and Applications

-

The Future of Automation: How Servo Valves are Revolutionizing Industry Efficiency

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance

-

Why You Should Invest in a Hydraulic Unit for Efficient Machinery Operation

-

Understanding Yuken Directional Valves and Their Applications in Modern Hydraulic Systems