- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

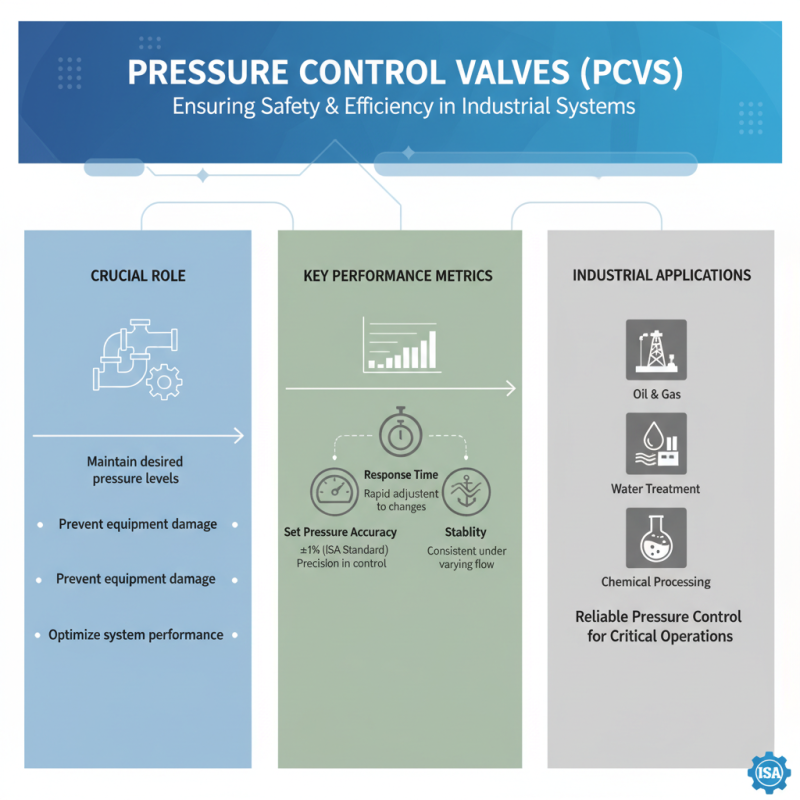

Understanding Pressure Control Valves: Types, Functions, and Applications

Pressure control valves are essential components in various industrial applications, serving to regulate and maintain pressure levels within systems. As explained by industry expert Dr. Emily Harrison, a leading authority in fluid dynamics, "The efficiency of any hydraulic system hinges on the effectiveness of its pressure control valve." This underscores the critical role these devices play in ensuring optimal performance and safety across different operational environments.

Understanding the different types of pressure control valves, their specific functions, and the wide array of applications they serve is vital for engineers and technicians alike. From ensuring safety in high-pressure systems to enhancing the efficiency of hydraulic circuits, pressure control valves are fundamental to maintaining stability and control. In this article, we delve into various pressure control valve designs, their respective functionalities, and the sectors where they are most commonly employed, highlighting their significance in industrial processes and everyday applications.

Table of Contents

[Hide]

Types of Pressure Control Valves and Their Specific Uses in Industries

Pressure control valves are crucial components in various industrial processes, ensuring safe and efficient operation by regulating fluid pressure. Among the different types, the most commonly used are relief valves, reducing valves, and sequence valves. Relief valves are designed to release excess pressure to protect equipment from damage, while reducing valves lower the pressure of a fluid to a desired level for downstream devices. Sequence valves control the operation of multiple systems by allowing one function to occur only after another has reached a specified pressure.

In sectors like oil and gas, precise pressure management is vital. According to a recent industry report, improper pressure control can lead to a 15% increase in operational costs. Sequence valves play a significant role in hydraulic systems by ensuring that processes occur in the correct order, enhancing efficiency and reducing wear and tear on machinery. Furthermore, relief valves are essential in the chemical industry for maintaining safety standards, as they prevent potentially hazardous scenarios caused by pressure surges.

Tips: When selecting a pressure control valve, consider the specific requirements of your application, such as the type of fluid, pressure ranges, and response time. Regular maintenance of these valves also ensures reliable performance and extends their lifespan, minimizing expensive downtime. Keeping accurate pressure measurement systems integrated with your valves can help in making informed decisions for optimal operation.

Types of Pressure Control Valves and Their Applications in Various Industries

Understanding the Mechanisms: How Pressure Control Valves Operate

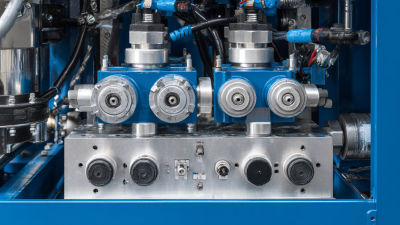

Pressure control valves (PCVs) play a critical role in maintaining system stability across various industrial applications. These valves operate by regulating the pressure of fluids, ensuring that it remains within a desired range. The mechanism behind PCVs typically involves pneumatic or hydraulic control systems that respond to changes in pressure. When the pressure exceeds a specified threshold, the valve adjusts its position to release excess pressure, thereby preventing potential system failures. According to the latest market analysis by Global Industry Analysts, the demand for pressure control valves is projected to reach USD 9.5 billion by 2027, highlighting their growing importance across sectors such as oil and gas, water treatment, and manufacturing.

Understanding the mechanisms at play helps in optimizing the performance and lifespan of pressure control valves. Most PCVs utilize a spring-loaded design, where a spring's tension can be adjusted to set the desired pressure level. When the internal pressure rises, the valve opens, allowing fluid to escape, reducing pressure to the set point. Conversely, when pressure drops, the valve closes, restricting flow. As reported by the Fluid Power Journal, proper calibration and regular maintenance of these valves can reduce unexpected downtime by up to 30%.

Tips: To maximize the efficiency of pressure control valves, ensure regular inspections and calibrations according to manufacturer recommendations. Additionally, consider the operating environment when selecting materials for the valves to prevent corrosion and wear. Maintaining a consistent monitoring system can also help in identifying pressure fluctuations before they become critical, ensuring system reliability in the long term.

The Importance of Pressure Regulation in Industrial Applications

Pressure regulation is a critical aspect of various industrial applications, ensuring systems operate efficiently and safely. In industries such as chemical manufacturing, oil and gas, and food processing, precise pressure control is vital for maintaining optimal operating conditions. Pressure control valves play a crucial role in managing the pressure within pipelines and vessels, preventing overpressure situations that could lead to hazardous failures or inefficiencies.

Effective pressure regulation helps protect equipment, enhances the safety of operations, and improves product quality. For instance, in chemical processing, maintaining specific pressure levels is essential to prevent reaction hazards and ensure that products meet stringent quality standards. Moreover, in systems that involve the transportation of gases or liquids, such as HVAC systems or hydraulic systems, regulated pressure avoids unnecessary strain on components, extending their lifespan and reducing the likelihood of maintenance issues. Understanding the importance of pressure control allows industries to adopt suitable technologies and practices, ultimately driving efficiency and reliability in their operations.

Key Performance Metrics and Standards for Pressure Control Valves

Pressure control valves (PCVs) play a crucial role in various industrial applications, maintaining desired pressure levels within systems to ensure safety and efficiency. Key performance metrics for these valves include set pressure accuracy, response time, and stability under varying flow conditions. According to the International Society of Automation (ISA), valves can achieve set point accuracy within ±1% under optimal conditions, highlighting the importance of precision in applications such as oil and gas, water treatment, and chemical processing.

Additionally, standards such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) provide frameworks for testing and evaluating pressure control valves. For instance, ISO 5208 outlines the testing methods for shut-off valves, impacting their reliability in pressure regulation. Reports indicate that valves meeting ISO standards tend to display enhanced mechanical performance and reduced failure rates, critical for applications demanding high reliability, like in pharmaceutical manufacturing where adherence to stringent quality controls is paramount. This emphasizes the need for industries to prioritize both performance metrics and compliance with established standards when selecting pressure control valves.

Future Trends and Innovations in Pressure Control Valve Technology

The future of pressure control valve technology is poised for significant advancements, driven by the increasing demands for efficiency, reliability, and automation across various industries. One of the most notable trends is the integration of smart technology into pressure control systems. These valves are becoming equipped with sensors and IoT capabilities that allow for real-time monitoring and data collection. This enhancement not only facilitates predictive maintenance but also enables users to optimize pressure settings dynamically, thereby improving overall system efficiency and reducing operational costs.

Moreover, the push for sustainability is influencing the design and functionality of pressure control valves. Manufacturers are focusing on developing eco-friendly materials and energy-efficient models that contribute to lower carbon footprints. Innovations such as advanced sealing technologies and corrosion-resistant materials are becoming more commonplace, thereby extending the lifespan of these components and enhancing their performance in harsh environments. As industries increasingly prioritize sustainability, the pressure control valve sector is likely to see continued innovations that align with these environmental goals, ensuring a balance between functionality and ecological responsibility.

Understanding Pressure Control Valves: Types, Functions, and Applications - Future Trends and Innovations in Pressure Control Valve Technology

| Type of Valve | Function | Applications | Future Trends |

|---|---|---|---|

| Direct-acting Pressure Relief Valve | Maintains pressure in a fluid system by releasing excess pressure | Oil and gas, chemical processing, water treatment | Integration with IoT for real-time monitoring |

| Pilot-operated Control Valve | Uses a small pilot flow to control a larger flow | HVAC systems, industrial automation | Advanced materials for corrosion resistance |

| Electronic Pressure Control Valve | Provides precise pressure control using electronic feedback | Aerospace, automotive, manufacturing | Smart technology for predictive maintenance |

| Spring-return Pressure Regulator | Regulates pressure through a spring mechanism | Food processing, pharmaceuticals | Sustainable designs focusing on energy efficiency |

Related Posts

-

Unlocking Efficiency: The Vital Role of Hydraulic Pressure Relief Valves in Industrial Systems

-

Exploring Innovative Control Products: Transforming Industries with Smart Technology

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

The Essential Guide to Understanding Hydraulic Power Packs in Industrial Applications

-

7 Essential Tips for Mastering Hydraulic Controls in Your Projects

-

What is Control Products and How They Enhance Efficiency in Industrial Applications