- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

In the realm of modern industrial applications, hydraulic valves play a pivotal role in controlling the flow and direction of hydraulic fluid, thereby influencing the overall efficiency and functionality of machinery. These essential components serve as the brain behind hydraulic systems, ensuring precise operation across various sectors, from manufacturing to construction. Understanding the intricacies of hydraulic valves is crucial for engineers and operators alike, as their selection and application can greatly affect system performance and reliability. This article delves into the fundamental aspects of hydraulic valves, exploring their types, functions, and critical roles in enhancing industrial processes. By grasping the principles surrounding these vital components, stakeholders can make informed decisions, optimize system design, and ultimately improve operational outcomes.

Table of Contents

[Hide]

Key Functions of Hydraulic Valves in Industrial Systems

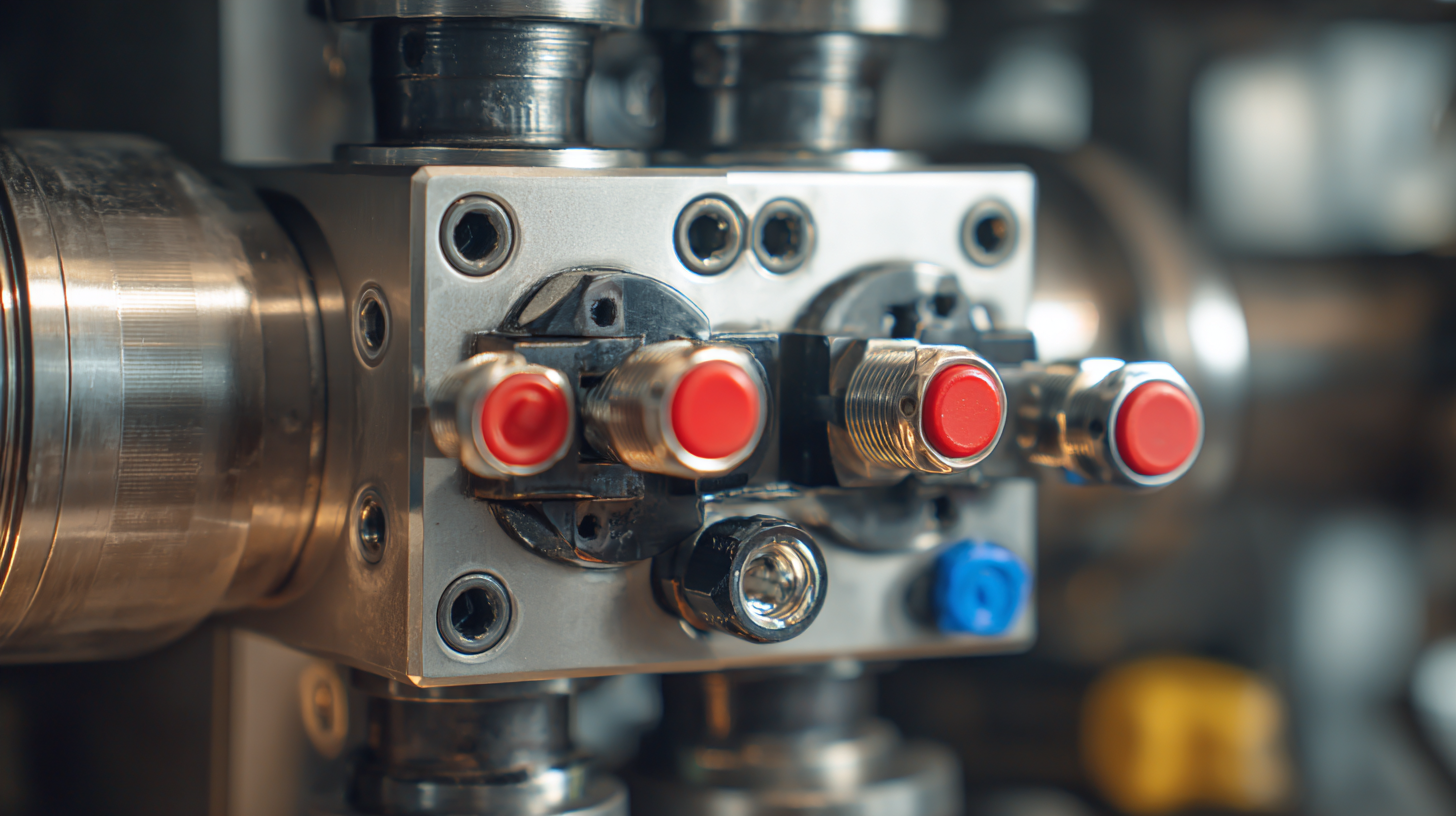

Hydraulic valves play a pivotal role in modern industrial applications by controlling the flow and pressure of hydraulic fluids within systems. One of their key functions is to direct the flow of hydraulic fluid to various components of a machine, ensuring that each part receives the required amount of power to operate efficiently. This precise control leads to enhanced performance and responsiveness in applications ranging from manufacturing machinery to automotive systems.

In addition to flow direction, hydraulic valves are essential for managing pressure levels within hydraulic circuits. They prevent excessive pressure buildup, which could otherwise lead to system failures or damage. By regulating pressure, these valves ensure safe operation and longevity of equipment. Furthermore, hydraulic valves often incorporate safety mechanisms, such as relief valves, which act as critical fail-safes in preventing catastrophic failures in industrial operations.

Overall, the functions of hydraulic valves are crucial in maintaining the efficiency and safety of modern industrial systems.

Types of Hydraulic Valves and Their Specific Applications

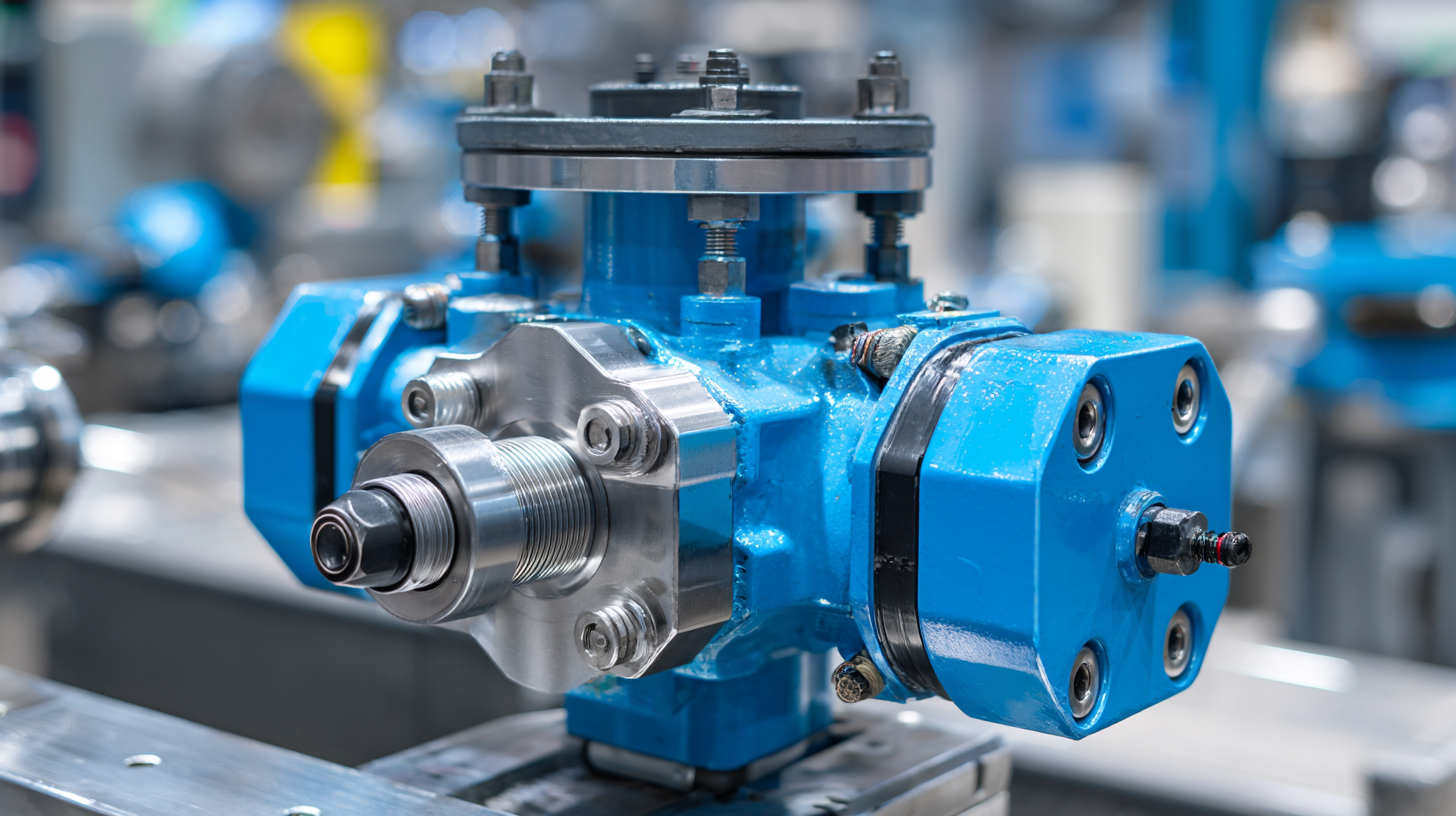

Hydraulic valves play a crucial role in modern industrial applications by controlling the flow and pressure of hydraulic fluids. There are several types of hydraulic valves, each designed for specific functions and applications. Directional control valves are among the most common, used to manage the flow path of hydraulic fluid within a system. According to a report from Research and Markets, the global directional control valve market is expected to reach $3.8 billion by 2026, underscoring their critical importance in industries such as construction and manufacturing.

Another significant type is pressure control valves, which regulate the pressure within hydraulic systems to prevent damage and ensure safety. These valves are essential in applications like hydraulic presses, where maintaining specific pressure levels is vital. A study by MarketsandMarkets indicates that the global pressure control valve market is projected to grow from $2.5 billion in 2021 to $3.9 billion by 2026, reflecting the increasing demand for safety and efficiency in hydraulic systems. Additionally, flow control valves, including throttling and check valves, help manage the rate of flow, playing a pivotal role in automation processes across various industrial sectors. As industries continue to enhance operational efficiency, the dependency on specialized hydraulic valves will only increase.

How to Choose the Right Hydraulic Valve for Your Needs

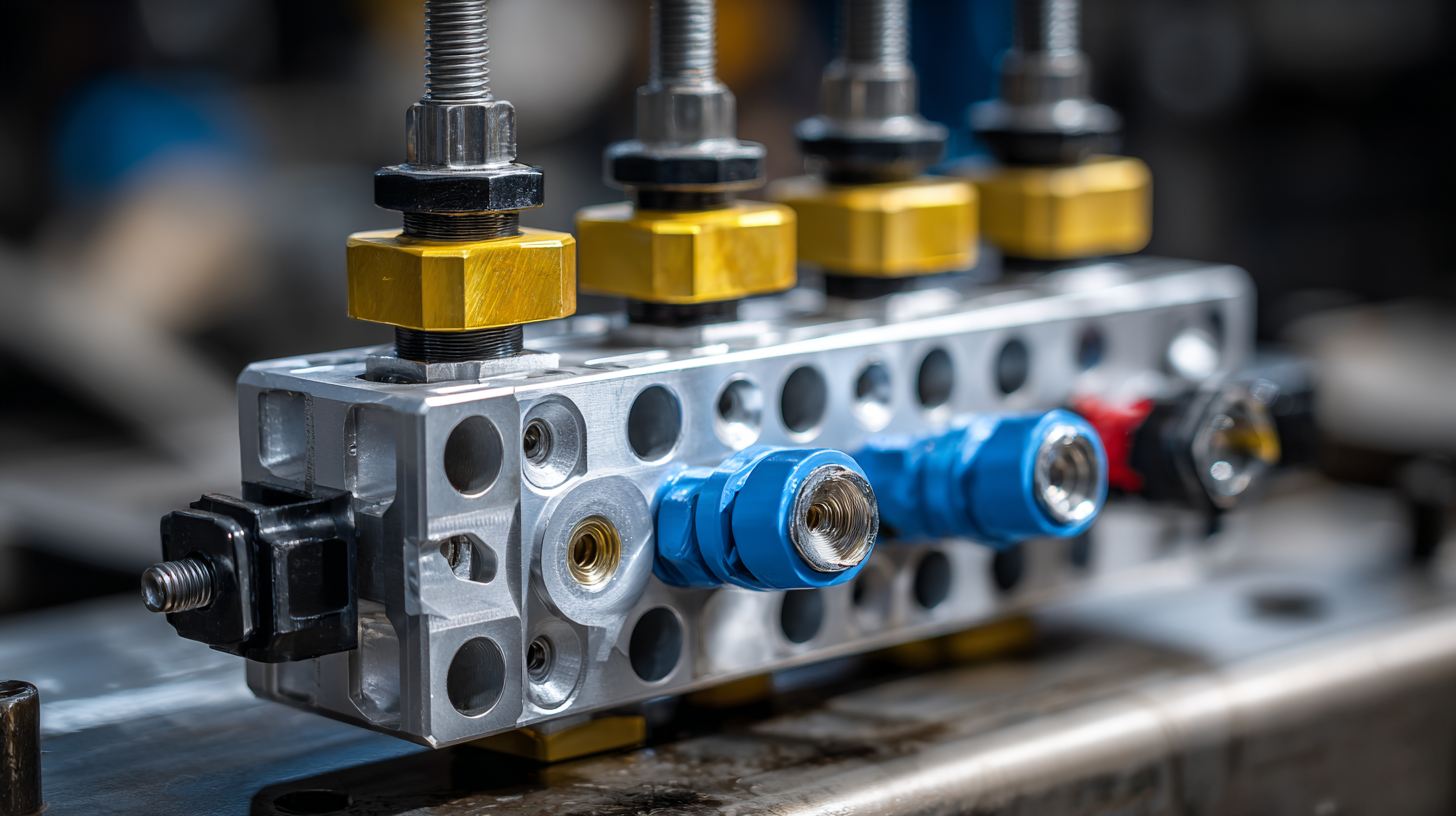

When selecting the right hydraulic valve for your needs, it is essential to understand the various types and their applications. Hydraulic valves come in numerous configurations, including directional control valves, pressure relief valves, and flow control valves. Each type serves a specific purpose, so assessing your system's requirements is crucial. For instance, if your application involves controlling the direction of fluid flow, a directional control valve would be appropriate. Conversely, if managing system pressure is paramount, a pressure relief valve may be the best choice.

In addition to type, factors such as size, material, and operating pressure must be considered when choosing a hydraulic valve. Valves must be compatible with the fluid used in the system and constructed from materials that can withstand the operating conditions. A valve that is too small may cause inefficiencies, while one that is too large could lead to pressure drops. Furthermore, consider the mode of operation—manual, pneumatic, or electronic control—and ensure that the selected valve integrates seamlessly with the rest of your hydraulic system. By carefully evaluating these aspects, you can successfully identify the hydraulic valve that best meets your operational demands.

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

This bar chart illustrates the percentage usage of different types of hydraulic valves in modern industrial applications. Understanding these percentages can help in selecting the right hydraulic valve for specific needs in various industrial processes.

Maintenance Best Practices for Hydraulic Valves in Industry

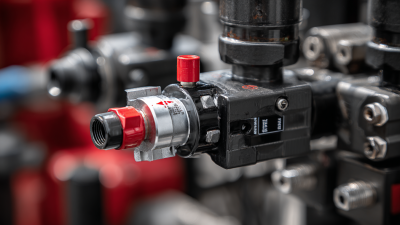

Hydraulic valves are critical components in various industrial applications, facilitating the control of fluid flow and pressure within hydraulic systems. Regular maintenance of these valves is essential to ensure optimal performance and longevity. One of the best practices for maintenance involves routine inspection for any signs of leaks, wear, or damage. Operators should monitor valve function closely, checking for unusual noises or irregularities that might indicate underlying issues. Regular cleaning of the valve surfaces and surrounding areas also helps prevent dirt and debris from affecting the valve's operation.

Hydraulic valves are critical components in various industrial applications, facilitating the control of fluid flow and pressure within hydraulic systems. Regular maintenance of these valves is essential to ensure optimal performance and longevity. One of the best practices for maintenance involves routine inspection for any signs of leaks, wear, or damage. Operators should monitor valve function closely, checking for unusual noises or irregularities that might indicate underlying issues. Regular cleaning of the valve surfaces and surrounding areas also helps prevent dirt and debris from affecting the valve's operation.

Another important maintenance practice is to follow the manufacturer's guidelines for lubrication and component replacement. Proper lubrication can prevent excessive wear and tear, extending the service life of the valve. Additionally, operators should maintain a log of maintenance activities and any issues that arise. This documentation can help identify recurring problems and inform future maintenance strategies.

Training personnel on these best practices ensures that every team member understands the importance of hydraulic valve upkeep, ultimately enhancing system reliability and efficiency in industrial settings.

Troubleshooting Common Issues with Hydraulic Valves

Hydraulic valves are vital components in modern industrial applications, notably in agricultural machinery, where they manage fluid flow and pressure throughout hydraulic systems. Common issues with hydraulic valves can lead to breakdowns at inconvenient times, impacting productivity significantly. For instance, a lack of regular maintenance can result in valve leakage or sticking, a concern recognized by 60% of operators in recent surveys indicating that inadequate servicing directly correlates with increasing repair costs.

Troubleshooting hydraulic valves involves understanding their role within the system. Many operators face challenges like erratic movement or unresponsive controls, often due to air trapped in the hydraulic fluid or contamination. Research highlights that implementing systematic diagnostic methods, such as 2D time-series modeling, can substantially enhance fault detection and reduce downtime. Additionally, recent developments in online training have emphasized the importance of hydraulic system maintenance and repair knowledge, which is now accessible to mechanics and operators eager to minimize the likelihood of operational failures.

Related Posts

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Unlocking Efficiency: The Vital Role of Hydraulic Pressure Relief Valves in Industrial Systems

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance

-

Maximizing Efficiency: How Directional Control Valves Transform Hydraulic Systems