- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

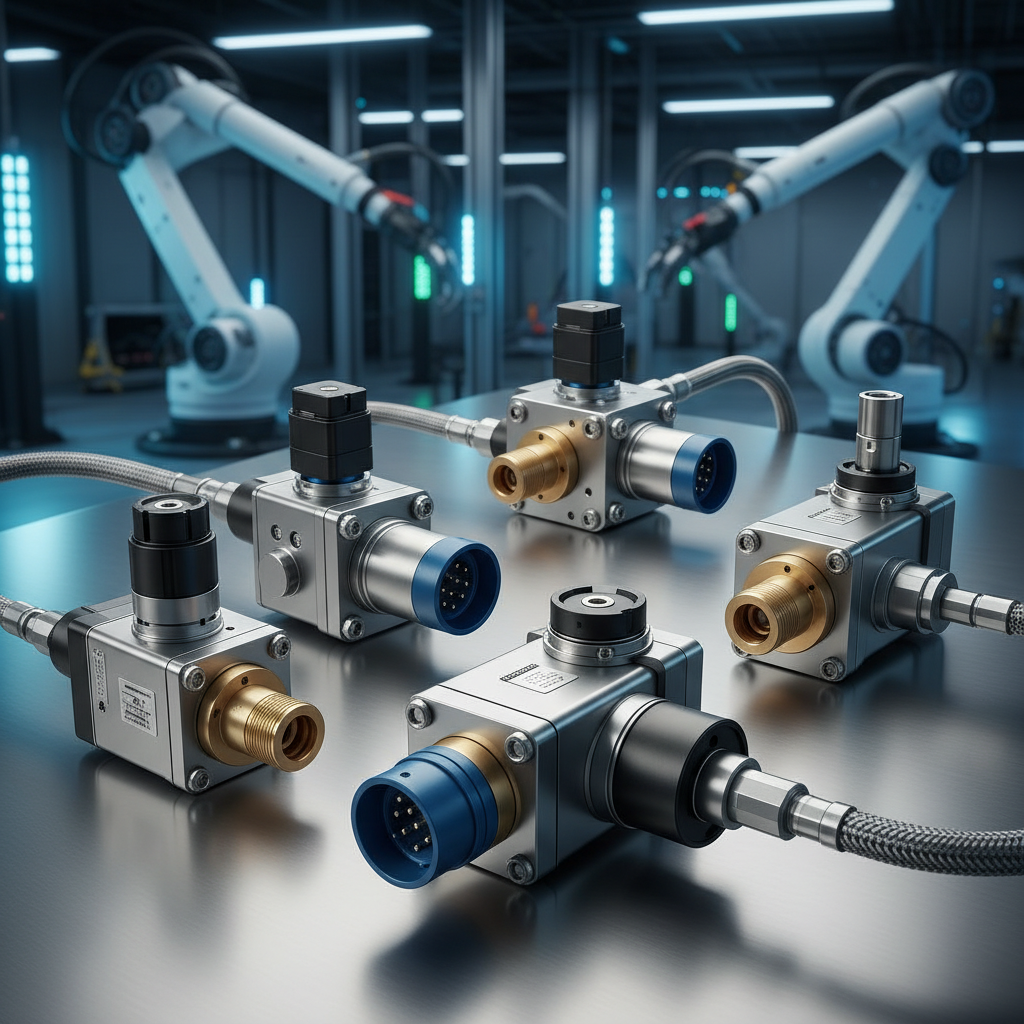

2025 Top 5 Proportional Valves to Enhance Your Industrial Efficiency

In the fast-evolving landscape of industrial automation, the importance of proportional valves cannot be overstated. These components are pivotal in enhancing the precision and efficiency of fluid control systems.

According to a recent market analysis by Global Industry Analysts Inc., the global proportional valve market is projected to reach USD 5.5 billion by 2025, driven by the increasing demand for automation across various sectors.

This significant growth underscores the necessity for industries to leverage advanced technologies, particularly in optimizing their operations.

Renowned industry expert Dr. Emily Rodriguez states, "The integration of proportional valves in automation processes is key to achieving unparalleled operational efficiency."

As industries aim to streamline processes and reduce costs, selecting the right proportional valve becomes critical. The 2025 landscape will see the emergence of innovative proportional valve designs and technologies that enhance responsiveness and accuracy, ultimately leading to improved productivity.

In this article, we delve into the top five proportional valves that promise to shape the future of industrial efficiency. By exploring their unique features and applications, we aim to provide insights that can enable businesses to make informed decisions and stay competitive in the market.

Table of Contents

[Hide]

Top Proportional Valve Types for Industrial Applications: A Comprehensive Overview

Proportional valves play a crucial role in enhancing industrial efficiency by providing precise control over fluid flow and pressure. These valves are essential in various applications such as automation systems, hydraulic machinery, and pneumatic operations. The ability to adjust flow rates in real time allows industries to optimize processes, reduce waste, and maintain consistent product quality.

There are several types of proportional valves suited for different industrial applications. Direct-acting proportional valves are commonly used for their simplicity and quick response times, making them ideal for smaller systems. Meanwhile, pilot-operated proportional valves are preferred in high-pressure applications due to their ability to handle larger flows and provide more robust performance. Additionally, electronically controlled proportional valves offer advanced functionality, enabling seamless integration with automated systems and enhancing operational precision. This diverse range of valve types ensures that industries can select the most suitable option for their specific needs, driving efficiency and productivity across the board.

Understanding the Working Mechanisms of Proportional Valves in Automation

Proportional valves play a crucial role in modern automation systems, allowing for precise control over flow rates and pressures in hydraulic and pneumatic applications. By adjusting the valve opening in proportion to an electrical signal, these valves facilitate a more accurate response to system demands compared to conventional on/off valves. This modulation enables smoother operation of machinery, reduces energy consumption, and minimizes wear on components, ultimately enhancing the overall efficiency of industrial processes.

The functionality of proportional valves is rooted in their sophisticated design, which typically includes a feedback mechanism that monitors the actual flow or pressure and adjusts the valve position accordingly. As the control signal fluctuates, the valve dynamically responds, ensuring that the output remains consistent with user requirements. This adaptability makes proportional valves ideal for applications requiring variable speed control, such as in automated assembly lines or robotic systems. By understanding the operational principles of these valves, businesses can strategically implement them to optimize their automation strategies, leading to increased productivity and reliability in industrial settings.

2025 Top 5 Proportional Valves to Enhance Your Industrial Efficiency

This bar chart illustrates the flow rates of the top 5 proportional valves for 2025. Understanding their performance can significantly enhance industrial efficiency in automation processes.

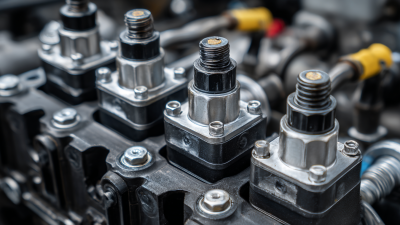

Evaluating Performance Metrics: Flow Control and Responsiveness in Valves

When evaluating proportional valves for industrial applications, two critical performance metrics come into play: flow control and responsiveness. Flow control is paramount, as it dictates how effectively a valve can regulate the fluid flow within a system. Valves must offer precise adjustments to maintain desired pressure and flow rates under varying operational conditions. High-quality proportional valves utilize advanced mechanisms to ensure consistent flow regulation, enabling processes to run smoothly and efficiently, ultimately enhancing overall productivity.

Responsiveness is equally vital, referring to a valve's ability to react swiftly to control signals. In fast-paced industrial environments, the speed at which a valve can adjust its position directly impacts system performance and reliability. Proportional valves with rapid responsiveness contribute to minimizing lag times during operation, ensuring that machinery can adapt to real-time demands.

This capability not only improves the efficiency of processes but also extends the lifespan of system components by reducing the wear caused by sluggish responses. By focusing on these performance metrics, industries can significantly boost their operational efficiency and reliability through the strategic selection of proportional valves.

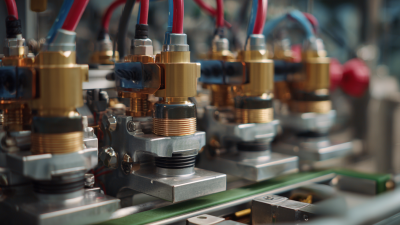

Comparative Analysis of Proportional Valve Materials for Enhanced Durability

In the realm of industrial automation, the choice of materials for proportional valves plays a pivotal role in determining their durability and performance. Enhanced durability is especially crucial in environments where valves are subject to high pressure and temperature fluctuations. Materials such as stainless steel, brass, and various engineered plastics are commonly employed, each offering distinct advantages. Stainless steel, for example, provides exceptional corrosion resistance and is ideal for harsh environments, ensuring a longer lifespan. In contrast, brass valves may offer better thermal conductivity and are often used in less aggressive applications.

The advancement in polymer science has also led to the development of high-performance plastics, which exhibit excellent chemical resistance and lower weight. These materials can significantly reduce operational wear, thereby enhancing the longevity and reliability of proportional valves. Moreover, the choice of sealing materials is equally critical; elastomers like Viton and Nitrile can withstand extreme conditions, further extending the service life of the valve. Ultimately, selecting the appropriate materials is essential for optimizing the efficiency and reliability of industrial systems, making informed decisions in this area a vital part of enhancing operational productivity.

2025 Top 5 Proportional Valves to Enhance Your Industrial Efficiency - Comparative Analysis of Proportional Valve Materials for Enhanced Durability

| Valve Model | Material | Pressure Rating (bar) | Temperature Range (°C) | Cycle Life (millions) |

|---|---|---|---|---|

| Model A | Aluminum Alloy | 350 | -20 to 80 | 10 |

| Model B | Stainless Steel | 400 | -40 to 120 | 15 |

| Model C | Brass | 300 | -10 to 90 | 8 |

| Model D | Polymer Composite | 250 | -30 to 70 | 12 |

| Model E | Titanium | 450 | -50 to 150 | 20 |

Market Trends and Projections for Proportional Valves in Industrial Efficiency by 2025

The proportional valves market is poised for significant growth by 2025, driven by advancements in automation and the increasing demand for precise control in industrial applications. As industries seek to enhance their operational efficiency, proportional valves are becoming a critical component in hydraulic and pneumatic systems. Trends indicate a shift towards more sophisticated electronic control systems that optimize performance and reduce energy consumption. This evolution aligns with the broader emphasis on sustainability and reducing the carbon footprint in manufacturing processes.

Moreover, the integration of IoT technologies is expected to revolutionize how proportional valves are employed in various industrial sectors. By enabling real-time monitoring and data collection, companies can make informed decisions regarding maintenance and system optimization. The projected rise in the adoption of smart manufacturing practices will further propel the demand for proportional valves that can seamlessly integrate with digital platforms. As we approach 2025, the market is likely to witness innovations that not only improve efficiency but also enhance the reliability and longevity of hydraulic and pneumatic systems.

Related Posts

-

2025 How to Choose the Best Yuken Valve for Your Hydraulic System

-

10 Essential Tips for Choosing the Right Pressure Reducing Valve

-

Understanding Yuken Directional Valves and Their Applications in Modern Hydraulic Systems

-

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

The Future of Automation: How Servo Valves are Revolutionizing Industry Efficiency