- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

What is a Yuken Directional Valve and How Does It Work?

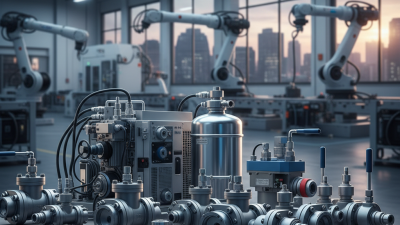

The Yuken directional valve is a key component in hydraulic systems. It controls fluid flow, impacting the operation of machinery. Understanding its functions can be crucial for technicians and engineers.

A Yuken directional valve typically features several ports. These allow hydraulic fluid to enter and exit in various directions. With its ability to control flow paths, it plays a critical role in automated systems. However, improper installation or maintenance can lead to inefficiencies.

Without a clear understanding, errors can occur. The complexity of the Yuken directional valve may overwhelm beginners. It takes practice to master its nuances. Everyone on the team should have basic knowledge of its workings. This ensures smooth operation and minimizes downtime.

Table of Contents

[Hide]

What is a Yuken Directional Valve?

A Yuken directional valve is an essential component in hydraulic systems. It controls the flow of pressurized fluid. This allows machinery to operate efficiently. These valves can direct fluid to different paths, depending on the system's needs.

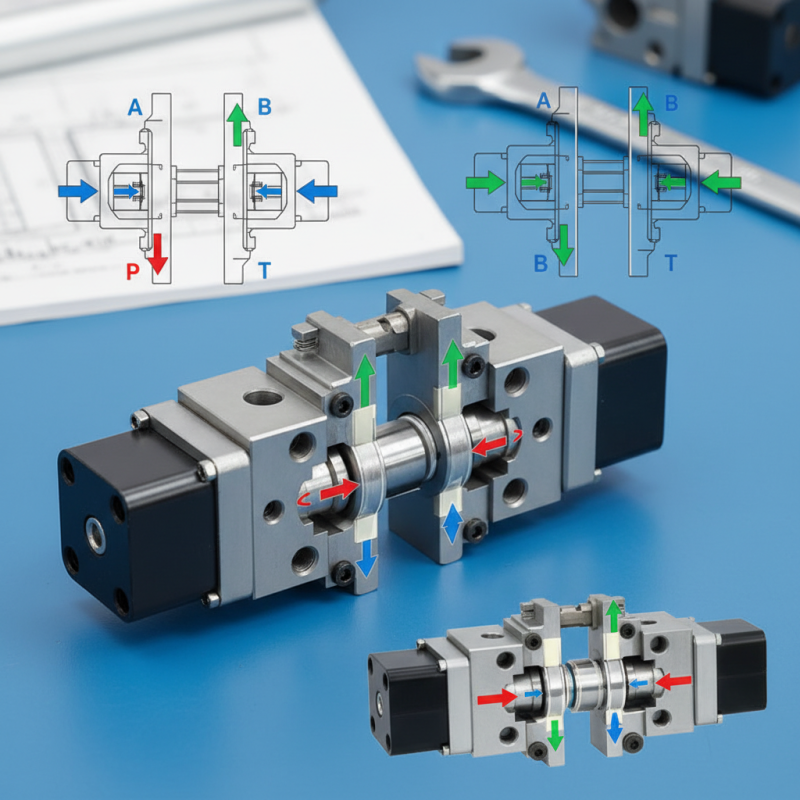

Understanding how a Yuken directional valve works is crucial. These valves contain a spool that shifts positions. This movement either opens or blocks certain passages. When engaged, the valve allows fluid to flow smoothly. When not, it stops the flow entirely. Simple, but crucial for performance.

**Tip:** Regular maintenance is essential for optimal performance. Check for leaks or obstructions. A small issue can lead to bigger problems down the line.

Furthermore, Yuken valves can vary in complexity. Some are manual, while others are electrically controlled. A proper understanding of both types is necessary. A mistake in choosing the right type could derail a project.

**Tip:** Always consider your specific application. Matching the valve to your system is vital for efficiency.

Yuken Directional Valve Performance Analysis

This bar chart illustrates the performance metrics of a Yuken directional valve, including flow rate, pressure, response time, and operating temperature. These metrics are essential for assessing the efficiency and reliability of hydraulic systems utilizing Yuken valves.

Key Features of Yuken Directional Valves

Yuken directional valves are critical components in hydraulic systems. They control the flow of hydraulic fluid, directing it to various parts of the system. Understanding their key features helps optimize their application in industries such as manufacturing and construction.

One notable feature of Yuken directional valves is their precision control. They allow for accurate regulation of fluid flow and pressure. This precision is essential for applications that require exact movements, such as robotics. According to industry reports, systems utilizing advanced directional valves can improve efficiency by up to 30%. This statistic highlights the importance of selecting high-quality components in hydraulic systems.

Another key aspect is their durability. These valves are built to withstand high pressures and extreme conditions. However, regular maintenance is vital. Without it, even the best valves may fail. Many users overlook this, leading to costly downtime. In fact, maintenance costs can account for up to 15% of total operational expenses. Hence, acknowledging the need for consistent checks is essential for maximizing the lifespan and performance of these valves.

How Yuken Directional Valves Operate

Yuken directional valves are key components in hydraulic systems. They control the flow direction of fluid, directing it to various actuators. These valves come in different configurations. Their design impacts performance and efficiency.

Operating a Yuken directional valve requires an understanding of its mechanics. When an electrical signal is applied, the valve shifts positions. This action either allows or blocks fluid flow. A spool inside the valve moves to change flow paths. This movement is crucial for achieving the desired operation in a hydraulic circuit.

Tips: Regular maintenance is essential. Inspect valves for leaks or wear. Proper installation improves longevity.

Understanding pressure and flow is vital. Each system has unique requirements. Experimentation is sometimes necessary to refine settings. Mistakes lead to valuable lessons. Small adjustments can create significant changes in performance.

Tips: Keep a log of adjustments. Documenting changes will help in troubleshooting. This practice enhances system reliability.

Applications of Yuken Directional Valves in Industry

Yuken directional valves play a crucial role in various industrial applications. They control the direction of hydraulic fluid flow in systems like presses and machines. These valves help optimize performance and increase efficiency. For instance, in assembly lines, they can manage actuator movements, ensuring precise operations.

In construction machinery, Yuken valves are vital for steering and lifting movements. They enable quick and reliable responses, which are essential in dynamic environments. However, not every installation works flawlessly. Sometimes, improper maintenance leads to inconsistent performance. Regular checks can prevent these issues, ensuring smooth operation.

In agriculture, these valves assist in the functioning of tractors and harvesters. They help control implements with accuracy. Yet, there is potential for misuse if operators are not trained properly. Understanding valve operation is essential for maximizing benefits while minimizing risks. Engaging operators in training can be a game-changer.

Maintenance and Troubleshooting of Yuken Directional Valves

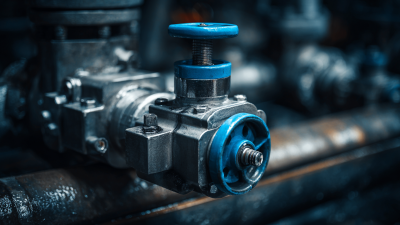

Maintaining a directional valve requires attention and care. Regular checks are vital. Start by inspecting the hydraulic fluid level. Low levels can cause operational issues. Look for leaks around the valve. Leaks may lead to system inefficiencies. Use a flashlight for detailed inspections.

Troubleshooting often begins with listening. Unusual noises signal problems. A whining sound might indicate air in the system or low fluid. Regular cleaning helps avoid dirt buildup. Contaminants can affect performance. Replace filters as needed. Aim for optimal flow and efficient operation.

Consider the performance indicators. If the valve is sluggish, assess the pressure settings. High pressure can lead to overheating. Monitor the temperature closely. An unexpected rise in temperature may signal trouble. These details are crucial. Neglecting them can result in more significant failures down the line.

Related Posts

-

Why Choose Yuken Valves for Your Industrial Applications

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance

-

2025 How to Choose the Best Yuken Valve for Your Hydraulic System

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications