- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Understanding Yuken Directional Valves and Their Applications in Modern Hydraulic Systems

In the rapidly evolving landscape of hydraulic systems, Yuken directional valves have emerged as a crucial component in enhancing operational efficiency and precision. As reported by the International Hydraulic and Pneumatics Society, the global hydraulic valve market is projected to reach $6.14 billion by 2027, with a significant share attributed to advanced technologies such as Yuken directional valves. These valves play a pivotal role in controlling fluid flow and pressure across various applications, enabling businesses to optimize their hydraulic systems for more predictable and reliable performance. Understanding the functionality and advantages of Yuken directional valves will not only aid manufacturers and engineers in decision-making processes but also contribute to the overall effectiveness and longevity of hydraulic applications in industries ranging from manufacturing to agriculture. As such, recognizing their potential is essential for anyone involved in the design and implementation of hydraulic solutions.

Table of Contents

[Hide]

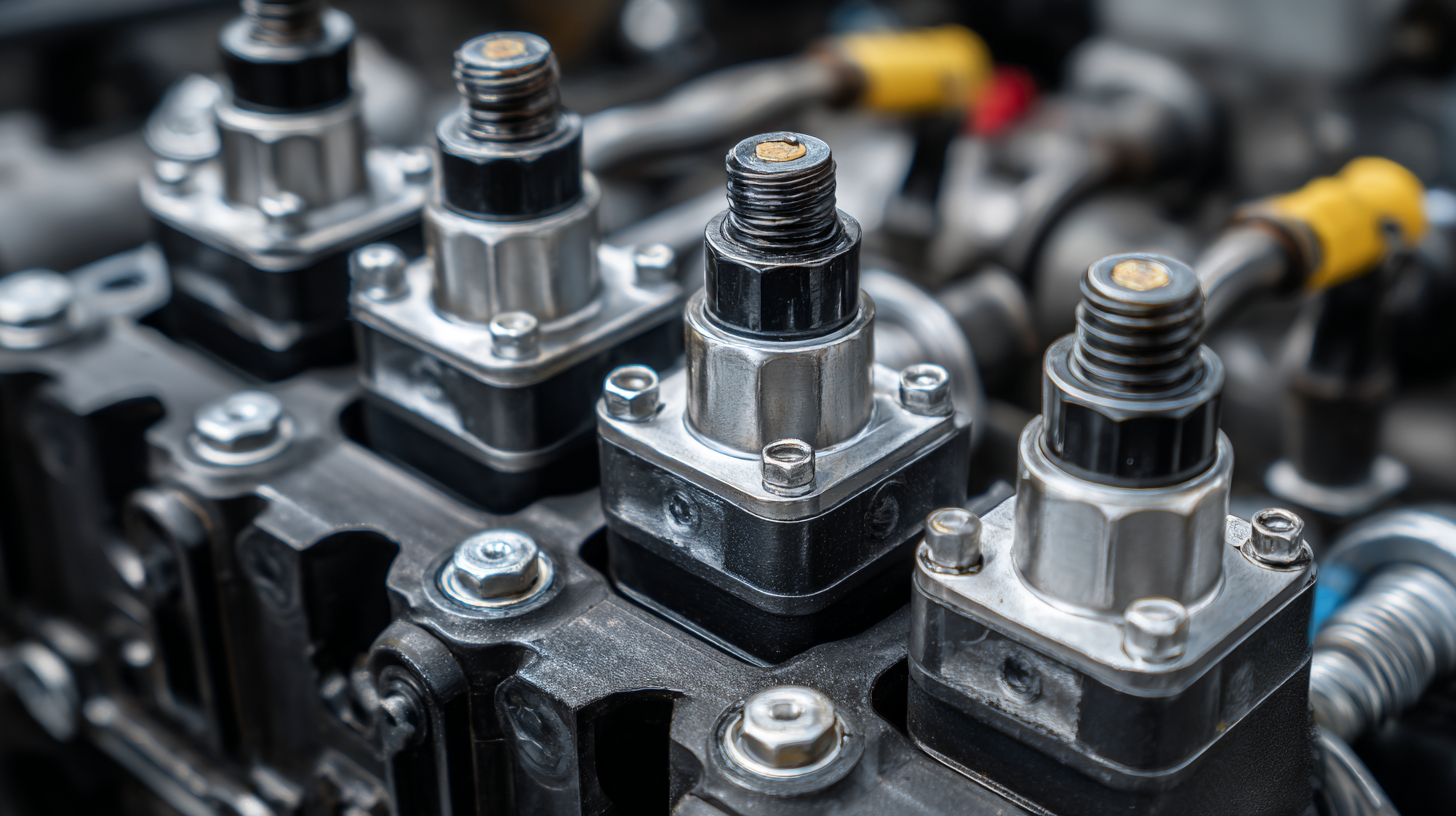

Key Features and Functionality of Yuken Directional Valves in Hydraulic Systems

Yuken directional valves play a critical role in modern hydraulic systems, providing precise control over fluid flow direction, pressure, and volume. One of the key features of these valves is their ability to ensure optimal performance through high responsiveness and minimal leakage, which can result in energy savings of up to 30% when compared to traditional systems. Yuken valves are engineered for durability and reliability in various applications, including industrial machinery, mobile equipment, and automation systems.

Another significant functionality of Yuken directional valves is their versatility in design. They come in a range of configurations, such as spool-type and cartridge-type valves, catering to different system requirements. According to industry reports, approximately 70% of hydraulic system efficiency can be traced back to the valve selection, underscoring the importance of choosing the right Yuken product to match specific application needs.

Tips: When selecting Yuken directional valves, consider the flow rate and pressure requirements of your system. Make sure to match the valve specifications with those of other hydraulic components for optimal performance. Additionally, regularly schedule maintenance checks to ensure that the valves remain in peak condition, which can extend their lifespan and enhance system efficiency.

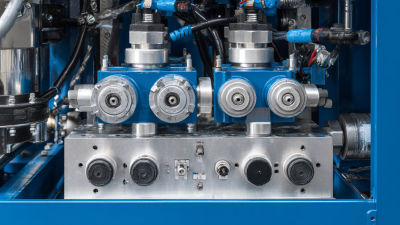

Industry Applications of Yuken Directional Valves in Manufacturing and Automation

Yuken directional valves play a crucial role in modern manufacturing and automation systems, facilitating precise control over hydraulic fluid flow. According to a report by ResearchAndMarkets, the global hydraulic valves market is expected to reach $7.92 billion by 2027, growing at a CAGR of 5.2% from 2020. This growth is largely driven by the increasing demand for automation in the manufacturing sector, where Yuken valves are effectively utilized to optimize machine performance and enhance operational efficiency.

In applications such as injection molding, metalworking, and material handling, Yuken directional valves provide reliable solutions that enhance productivity. For instance, in automotive manufacturing, a sector projected to grow at a rate of 4% annually, the use of advanced hydraulic systems equipped with Yuken valves ensures faster cycle times and improved energy efficiency. Yuken's innovative designs, including compact configurations and varied actuator options, make them indispensable in complex hydraulic networks, meeting the rising expectations for automation and precision in various industries.

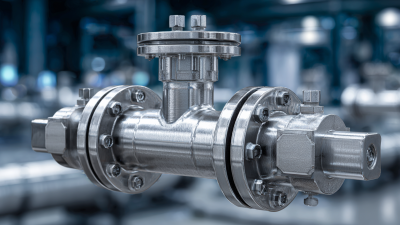

Performance Metrics: Efficiency and Response Times of Yuken Directional Valves

Yuken directional valves are a cornerstone in modern hydraulic systems, known for their ability to control fluid flow direction with precision. One of the key performance metrics of these valves is their efficiency, which is often quantified as the ratio of useful output to energy input. According to a recent industry report by Fluid Power Journal, Yuken valves exhibit efficiencies exceeding 90%, largely due to their innovative design and high-quality hydraulic seals that minimize leakage and energy loss. This efficiency translates into reduced operational costs and improved system performance, crucial for industries relying on hydraulic mechanisms.

Yuken directional valves are a cornerstone in modern hydraulic systems, known for their ability to control fluid flow direction with precision. One of the key performance metrics of these valves is their efficiency, which is often quantified as the ratio of useful output to energy input. According to a recent industry report by Fluid Power Journal, Yuken valves exhibit efficiencies exceeding 90%, largely due to their innovative design and high-quality hydraulic seals that minimize leakage and energy loss. This efficiency translates into reduced operational costs and improved system performance, crucial for industries relying on hydraulic mechanisms.

Another critical performance metric is response time, which is vital for applications requiring immediate and accurate control. Yuken directional valves typically achieve response times as low as 15 milliseconds, making them suitable for applications in manufacturing automation and mobile machinery. The rapid actuation time ensures that the hydraulic systems maintain high productivity levels while minimizing delay in operation.

Tips: When selecting a Yuken directional valve, prioritize models that fit your specific application needs. Consider factors such as maximum flow rates and operating pressures to ensure optimal performance. Regular maintenance checks can further enhance efficiency and reliability, extending the lifespan of your hydraulic components.

Comparative Analysis: Yuken Directional Valves vs. Competitors in Hydraulic Technology

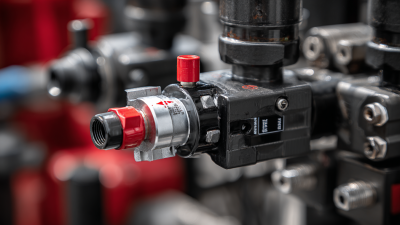

In the realm of hydraulic technology, Yuken directional valves have carved a niche for themselves, owing to their reliability and innovative design. Compared to competitors, Yuken valves often demonstrate superior performance in applications requiring precision control and efficiency. While many manufacturers offer a range of directional valves, Yuken stands out with its emphasis on durability and advanced hydraulic intuitiveness, ensuring minimal wear and optimal functionality over time.

One of the primary areas where Yuken valves excel is in energy efficiency. Their unique design principles reduce unnecessary pressure drops, allowing systems to operate smoothly while consuming less energy. This contrasts sharply with some competitors whose valves may experience greater energy losses during operation, leading to increased operational costs over time. Moreover, Yuken's commitment to incorporating the latest technology in their products, such as integrated sensors and smart controls, places them at the forefront of hydraulic innovation, giving them an edge over traditional models offered by other brands.

Understanding Yuken Directional Valves and Their Applications in Modern Hydraulic Systems - Comparative Analysis: Yuken Directional Valves vs. Competitors in Hydraulic Technology

| Feature | Yuken Directional Valves | Competitor A | Competitor B |

|---|---|---|---|

| Operating Pressure (MPa) | 31.5 | 32.0 | 30.0 |

| Flow Rate (L/min) | 120 | 130 | 110 |

| Response Time (ms) | 25 | 20 | 30 |

| Weight (kg) | 3.5 | 3.8 | 3.2 |

| Temperature Range (°C) | -20 to 80 | -25 to 85 | -20 to 75 |

| Control Type | Electrical | Hydraulic | Pneumatic |

Future Trends: Innovations in Yuken Directional Valves for Enhanced Hydraulic Performance

The future of hydraulic systems is poised for transformative advancements, particularly with innovations in Yuken directional valves. As industries increasingly prioritize efficiency and sustainability, the demand for enhanced hydraulic performance has surged. Yuken, a prominent player in hydraulic technology, is at the forefront of developing valves that not only optimize fluid control but also reduce energy consumption and emissions. According to a recent report by the International Fluid Power Association, the global hydraulic market is projected to reach $60 billion by 2025, fostered by innovations like Yuken’s energy-efficient directional valves.

Recent developments have introduced smart technology and IoT integration into Yuken directional valves, allowing for real-time monitoring and adjustments in hydraulic systems. This leads to greater precision in operations and enhanced reliability, responding to the growing trend towards automation in manufacturing processes. The integration of predictive maintenance—by analyzing operational data—can potentially reduce downtime by up to 30%, as highlighted in a study from the National Institute of Standards and Technology. As Yuken continues to evolve its product offerings, the hydraulic industry can look forward to smarter, more efficient systems that align with modern operational needs.

Related Posts

-

Understanding the Role of Check Valves in Modern Industrial Systems

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Maximizing Efficiency: How Directional Control Valves Transform Hydraulic Systems

-

The Essential Guide to Understanding Hydraulic Power Packs in Industrial Applications

-

Unlocking Efficiency: The Vital Role of Hydraulic Pressure Relief Valves in Industrial Systems

-

Exploring Innovative Control Products: Transforming Industries with Smart Technology